Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

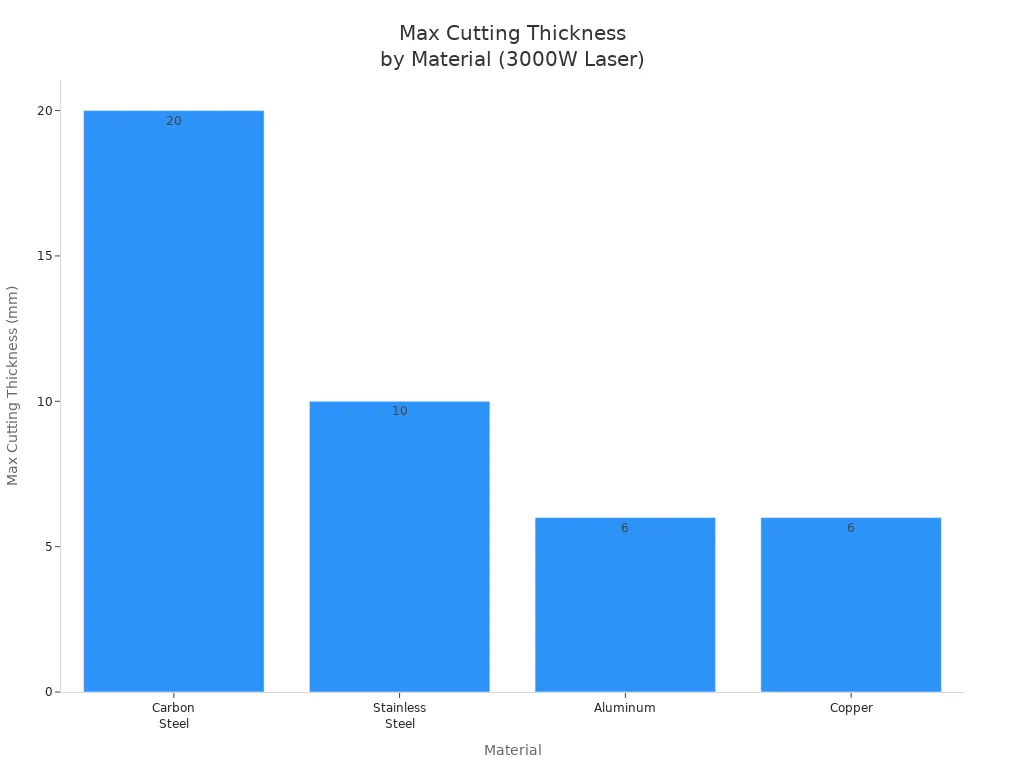

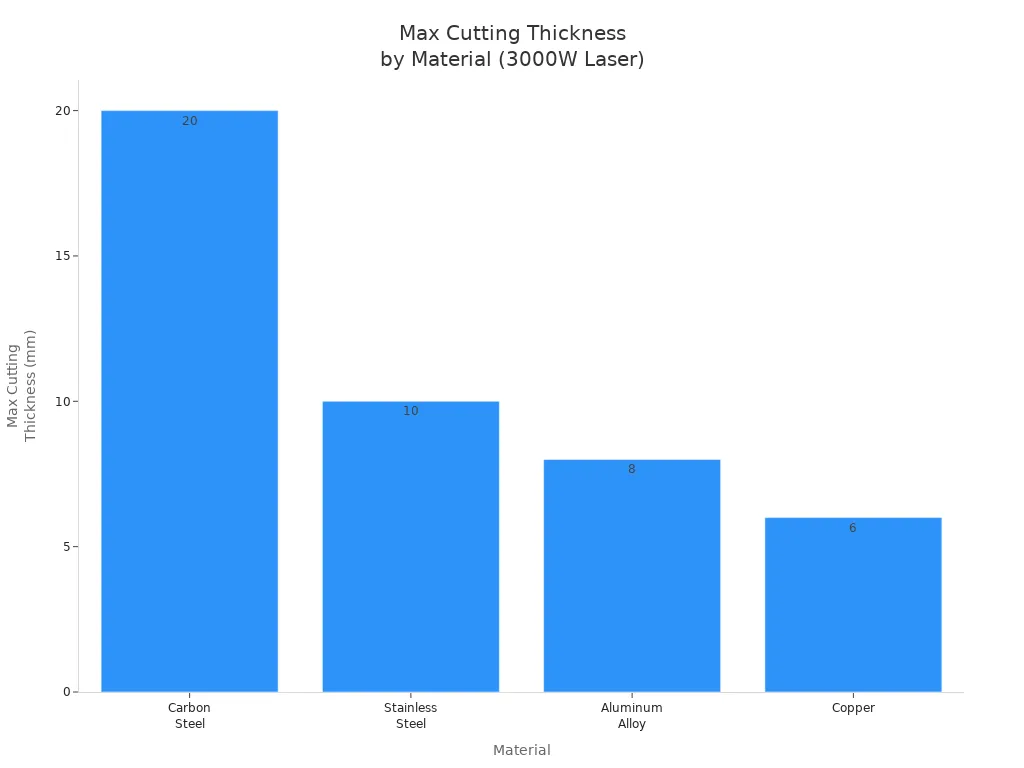

You need a fiber laser machine that delivers reliable cutting thickness across various materials. With a 3000W system, you achieve maximum cutting thickness of 20mm for carbon steel, 10mm for stainless steel, and 6mm for both aluminum and copper. The minimum cutting thickness for all these materials starts at 0.5mm, ensuring flexibility in your process. Cutting quality depends on machine quality, process settings, and assist gas. Review the summary below for precise maximum and minimum cut values:

| Material | Maximum Cutting Thickness | Minimum Cutting Thickness |

|---|---|---|

| Carbon Steel | 20mm | 0.5mm |

| Stainless Steel | 10mm | 0.5mm |

| Aluminum | 6mm | 0.5mm |

| Copper | 6mm | 0.5mm |

When you use a 3000W fiber laser cutting machine, you can achieve impressive results on carbon steel. The maximum cutting thickness for carbon steel reaches up to 20mm. This capability allows you to handle a wide range of industrial tasks, from heavy-duty fabrication to precision engineering. Many manufacturers, including Guangdong Jinan Pioneer CNC Technology Co., Ltd, design their machines to deliver consistent performance at this level. You will notice that the maximum cutting thickness depends on several factors, such as the quality of the laser source, the stability of the machine bed, and the type of assist gas used. For example, using oxygen as an assist gas can help you reach the max carbon steel thickness efficiently. When you cut thicker carbon steel, you should expect slower speeds, but the results remain reliable. The cutting thickness for carbon steel sets the benchmark for fiber laser cutting in industrial environments.

You can also achieve precise cuts on thin carbon steel sheets. The minimum cutting thickness starts at 0.5mm. This flexibility means you can process delicate components without sacrificing edge quality. When you cut thin materials, you benefit from high speed and clean edges, which are essential for applications like automotive panels or electronic enclosures. The ability to handle both the maximum and minimum cutting thickness gives you a competitive edge when cutting various materials.

Stainless steel presents unique challenges due to its reflective surface and thermal properties. With a 3000W fiber laser cutting machine, you can reach a maximum cutting thickness of 10mm for stainless steel. This level of performance is ideal for industries that require both strength and corrosion resistance, such as medical device manufacturing and food processing equipment. The cutting thickness of stainless steel depends on the purity of the material, the type of assist gas (usually nitrogen or oxygen), and the precision of the laser optics. You will find that fiber laser cutting offers superior edge quality and minimal heat-affected zones, even at the maximum thickness. This advantage makes fiber laser cutting the preferred choice for cutting various materials in demanding environments.

You can cut stainless steel sheets as thin as 0.5mm. This minimum cutting thickness ensures you can produce intricate parts with high accuracy. When you work with thin stainless steel, you achieve fast processing speeds and polished edges. The versatility of fiber laser cutting allows you to switch between different materials and thicknesses with minimal setup time.

Aluminum requires careful handling due to its high reflectivity and thermal conductivity. With a 3000W fiber laser cutting machine, you can achieve a maximum cutting thickness of 6mm. This capability covers most industrial applications, including aerospace components and architectural panels. The maximum cutting thickness for aluminum depends on the quality of the optics and the use of nitrogen as an assist gas. You will notice that fiber laser cutting provides clean, burr-free edges on aluminum, even at the maximum thickness. This performance makes it easier for you to meet strict quality standards when cutting various materials.

You can cut aluminum sheets down to 0.5mm. This minimum cutting thickness allows you to create lightweight, precise parts for specialized applications. When you cut thin aluminum, you benefit from high speed and excellent edge quality. The ability to handle a wide range of cutting thicknesses makes fiber laser cutting a versatile solution for processing different materials.

Tip: Always match your machine settings to the specific material and thickness you are cutting. This practice ensures optimal results and extends the life of your fiber laser cutting equipment.

When you cut copper with a 3000W fiber laser machine, you reach a maximum thickness of 6mm to 8mm. This range depends on the quality of your equipment, the purity of the copper, and the type of assist gas you use. Copper reflects laser light more than other metals, so you need a machine with advanced optics and stable power delivery. Guangdong Jinan Pioneer CNC Technology Co., Ltd designs its fiber laser machines to handle these challenges. You get consistent results even when working at the upper end of the thickness range.

Note: Using nitrogen as an assist gas helps you achieve cleaner edges and reduces oxidation on copper surfaces.

You often see the best results when you cut copper sheets up to 6mm thick. If you push the machine to 8mm, you may notice a slight drop in edge quality or cutting speed. Industrial-grade machines with water-cooled lasers and heavy-duty frames maintain stability and precision, even at maximum thickness. This performance gives you a clear advantage in industries like electrical manufacturing, where copper parts must meet strict standards.

You can cut copper sheets as thin as 0.5mm with a 3000W fiber laser. This capability allows you to produce intricate components for electronics, connectors, and decorative items. Thin copper requires precise control of laser power and speed. You avoid warping and achieve smooth, burr-free edges by fine-tuning your machine settings.

For thin copper, use lower power settings and faster cutting speeds.

Always check the focus of the laser beam to ensure clean cuts.

Keep your optics clean to prevent reflection issues.

You benefit from the flexibility to switch between thick and thin copper materials without changing machines. This versatility saves you time and increases your productivity. With the right setup, you deliver high-quality copper parts for a wide range of industrial applications.

You need to understand how the properties of materials influence the cutting process. Each material reacts differently to a fiber laser machine. The following factors play a crucial role in determining both the maximum cutting thickness and the quality of the cut:

The reflectivity of materials affects how much laser energy gets absorbed. Highly reflective materials, such as copper, reflect most of the laser energy. This property makes it harder to cut and limits the maximum cutting thickness.

Materials with high thermal conductivity, like aluminum, dissipate heat quickly. You must adjust fiber laser power and cutting speeds to achieve the desired maximum thickness.

The density of materials impacts how much energy is required to penetrate them. Denser materials often require higher fiber laser power for effective cutting.

You will notice that the cutting process for each material requires careful adjustment of settings to maintain quality and reach the maximum thickness possible.

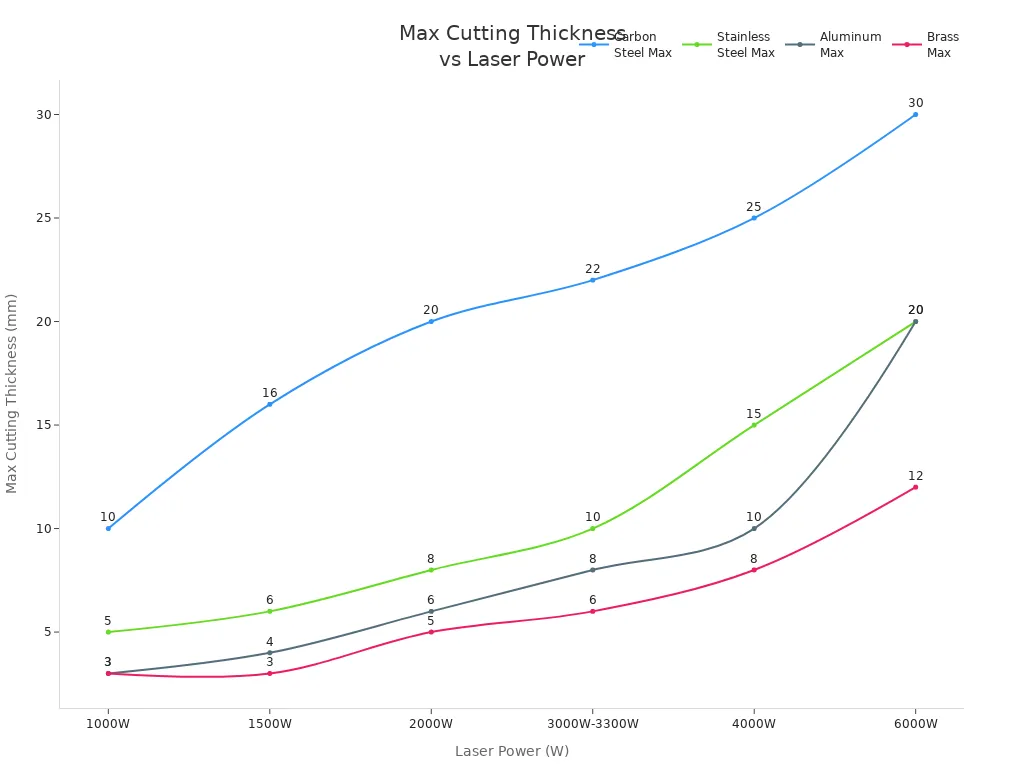

Fiber laser power directly impacts the maximum cutting thickness you can achieve. As you increase fiber laser power, you gain the ability to cut thicker materials while maintaining high quality. The table below shows how different power levels affect the maximum thickness for various materials:

| Laser Power (W) | Carbon Steel Thickness (mm) | Stainless Steel Thickness (mm) | Aluminum Thickness (mm) | Brass Thickness (mm) |

|---|---|---|---|---|

| 1000W | 0.8 – 10 | 0.8 – 5 | 0.8 – 3 | 1 – 3 |

| 1500W | 1 – 16 | 1 – 6 | 1 – 4 | 1 – 3 |

| 2000W | 1 – 20 | 1 – 8 | 1 – 6 | 1 – 5 |

| 3000W-3300W | 1 – 22 | 1 – 10 | 1 – 8 | 1 – 6 |

| 4000W | 1 – 25 | 1 – 15 | 1 – 10 | 1 – 8 |

| 6000W | 1 – 30 | 1 – 20 | 1 – 20 | 1 – 12 |

You see that a high-power fiber laser, such as a 3000W system, allows you to reach a maximum cutting thickness of up to 22mm for carbon steel and 10mm for stainless steel. This technology gives you flexibility in your cutting process and ensures consistent quality across a wide range of materials.

A high-power laser not only increases the maximum but also improves the quality of the cut at higher thicknesses. You benefit from faster cutting speeds and better edge quality, especially when working with demanding materials.

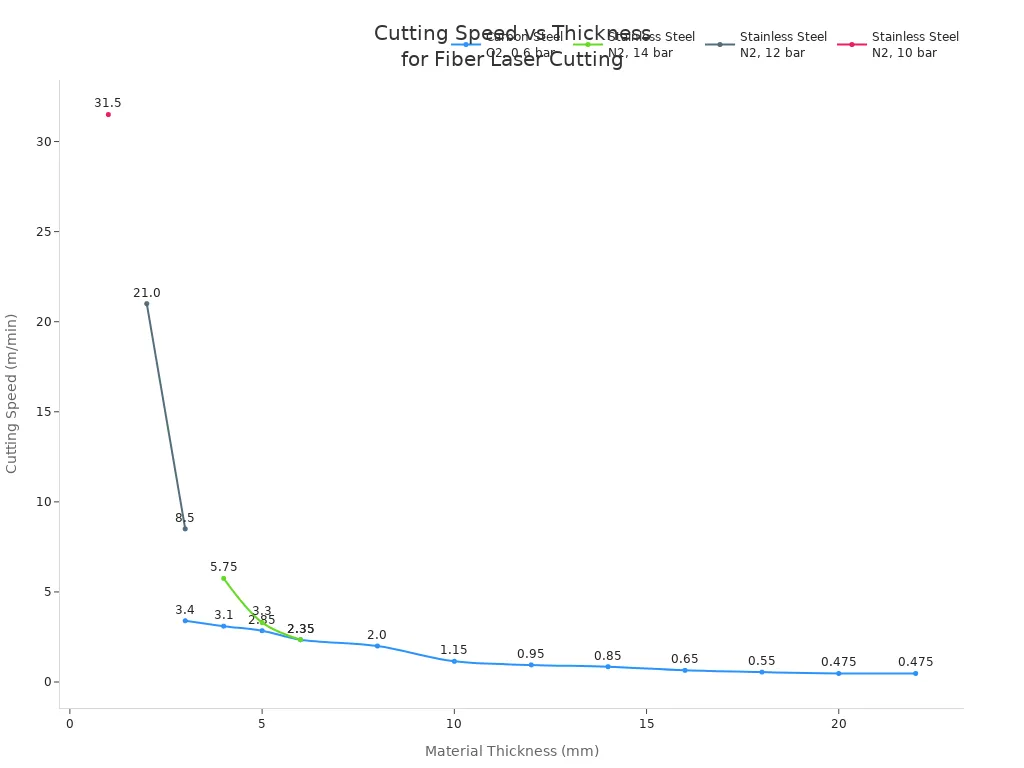

The type and pressure of assist gas you use in the cutting process have a significant effect on both maximum cutting thickness and quality. Assist gases, such as oxygen and nitrogen, help remove molten material and cool the cut zone. The table below highlights how assist gas impacts cutting speeds and maximum thickness for different materials:

| Material | Thickness (mm) | Cutting Speed (m/min) | Gas | Pressure (bar) |

|---|---|---|---|---|

| Carbon Steel | 1 | 28-35 | N2/Air | 10 |

| 2 | 16-20 | N2/Air | 10 | |

| 2 | 3.8-4.2 | O2 | 1.6 | |

| 10 | 1.0-1.3 | O2 | 0.6 | |

| 20 | 0.4-0.55 | O2 | 0.6 | |

| Stainless Steel | 1 | 28-35 | N2 | 10 |

| 6 | 2.0-2.7 | N2 | 14 |

You will find that using nitrogen as an assist gas produces clean, oxidation-free edges, which is essential for stainless steel and aluminum. Oxygen, on the other hand, increases the maximum cutting thickness for carbon steel but may affect edge quality. Adjusting gas pressure also helps you optimize the cutting process for different materials and thicknesses.

By selecting the right assist gas and pressure, you maximize both the quality and efficiency of your fiber laser cutting process. This approach ensures you achieve the desired maximum cutting thickness and maintain high-quality results across all materials.

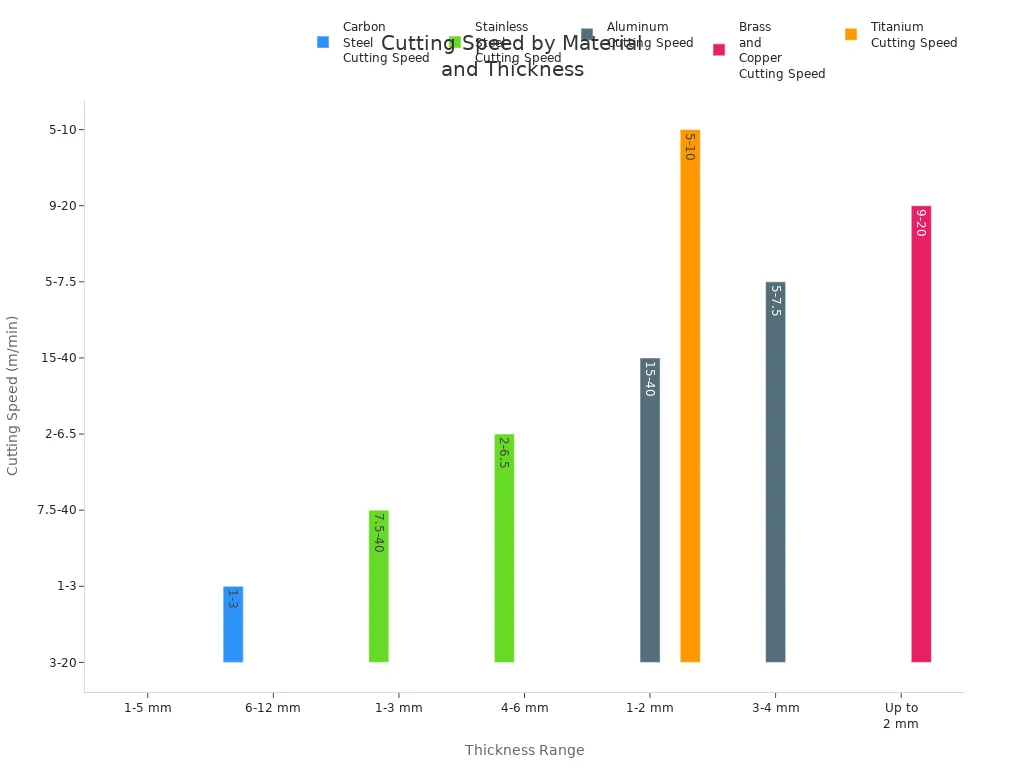

Cutting speed plays a critical role in determining both the maximum thickness you can cut and the quality of the finished edge. When you increase the cutting speed, you process thin materials quickly and efficiently. However, as the material becomes thicker or harder, you need to slow down the cutting speed to maintain precision and avoid defects like rough edges or incomplete cuts.

You will notice that each metal responds differently to changes in speed. For example, you can cut 1–5 mm carbon steel at speeds between 3 and 20 meters per minute. When you move to thicker carbon steel, such as 6–12 mm, the speed drops to 1–3 meters per minute. Stainless steel and aluminum allow for even higher speeds at thinner gauges, but you must reduce speed as thickness increases to ensure a clean, accurate cut.

Here is a summary of typical cutting speeds for various metals and thicknesses using a 3000W fiber laser:

| Material | Thickness Range | Cutting Speed (m/min) |

|---|---|---|

| Carbon Steel | 1-5 mm | 3-20 |

| 6-12 mm | 1-3 | |

| Stainless Steel | 1-3 mm | 7.5-40 |

| 4-6 mm | 2-6.5 | |

| Aluminum | 1-2 mm | 15-40 |

| 3-4 mm | 5-7.5 | |

| Brass and Copper | Up to 2 mm | 9-20 |

| Titanium | 1-2 mm | 5-10 |

As you adjust the speed, you must balance productivity with quality. Fast speeds work best for thin sheets, while slower speeds are necessary for thicker or more challenging materials. If you cut too quickly on thick metal, you risk poor edge quality or incomplete penetration. By fine-tuning the cutting speed, you achieve smooth, burr-free edges and consistent results across a range of materials.

Machine stability is essential for achieving consistent cutting thickness and high-quality results. When you operate a 3000W fiber laser, you rely on the machine’s structural integrity to minimize vibration and maintain precise movement. A stable machine frame ensures that the laser beam stays focused and the cutting path remains accurate, even during long production runs.

Key features that enhance machine stability include:

A stress-relieved welded bed frame that absorbs vibrations and resists deformation.

High-temperature annealing and a controlled aging process that increase rigidity and prevent warping over time.

Industrial-grade construction that supports heavy loads and maintains alignment during high-speed cutting.

These features work together to deliver reliable performance, especially when you cut at maximum thickness. You benefit from smoother edges, tighter tolerances, and fewer interruptions due to machine errors. By choosing a fiber laser machine with advanced stability features, you ensure that your cuts remain precise and your productivity stays high, even in demanding industrial environments.

You expect clean, smooth edges when you use a 3000W fiber laser machine. This level of fiber laser power delivers excellent results, especially on thicker materials. You notice that both 1500W and 3000W models produce high-quality cuts on thin and moderate materials. However, the 3000W system stands out when you cut thicker metals or need to maintain high throughput. You see minimal dross and burrs, which reduces the need for secondary finishing. In industries such as automotive and aerospace, this edge quality ensures your parts meet strict standards.

3000W fiber laser power maintains edge quality at higher speeds.

You achieve consistent results on carbon steel, stainless steel, aluminum, and copper.

Precision remains high, even as you increase material thickness.

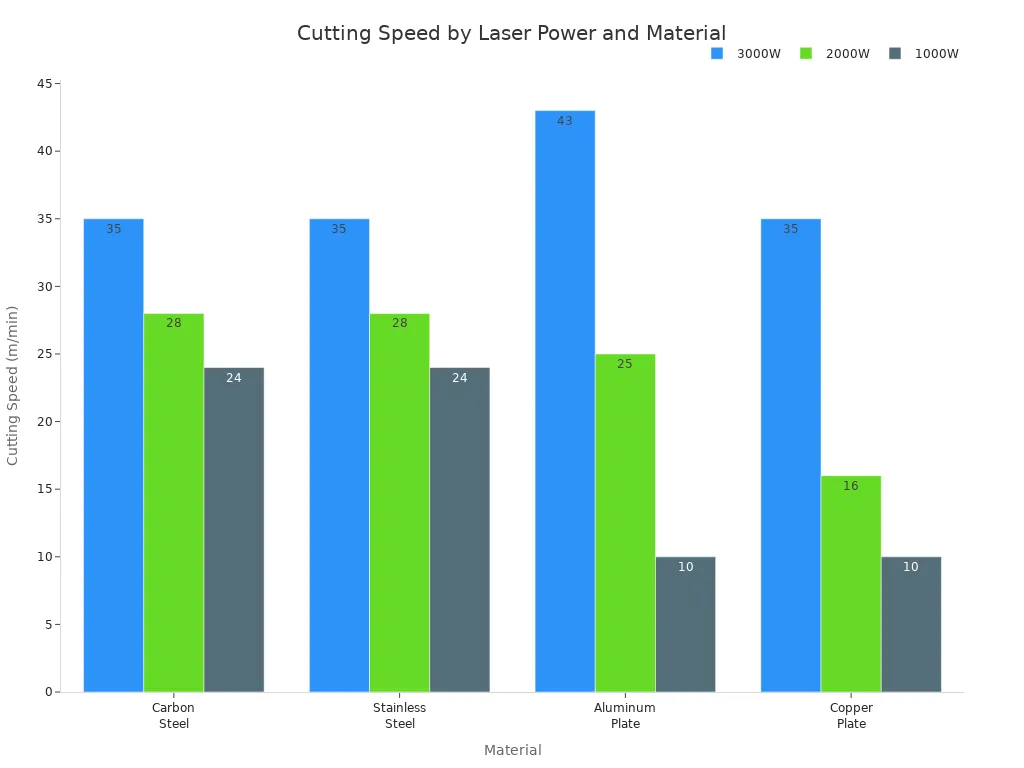

Speed is a major advantage of higher fiber laser power. You process jobs faster and boost productivity in your shop. The 3000W fiber laser cutting system outpaces lower-power models, especially on demanding materials. The table below shows how cutting speed improves as you move from 1000W to 3000W:

| Material | 3000W Speed (m/min) | 2000W Speed (m/min) | 1000W Speed (m/min) |

|---|---|---|---|

| Carbon Steel | 35 | 28 | 24 |

| Stainless Steel | 35 | 28 | 24 |

| Aluminum Plate | 43 | 25 | 10 |

| Copper Plate | 35 | 16 | 10 |

You see that higher fiber laser power not only increases speed but also expands the range of materials you can cut efficiently. This benefit is crucial for fabrication shops and high-volume production lines.

Precision defines the value of a modern fiber laser cutting system. You rely on tight tolerances for parts in automotive, aerospace, and energy sectors. With 3000W fiber laser power, you achieve tolerances as fine as ±0.05 mm. This level of accuracy minimizes distortion and ensures your components fit perfectly. You also benefit from the ability to cut intricate shapes and small features without sacrificing quality.

Fiber laser power at 3000W supports high-precision applications.

You meet the demands of industries that require strict quality control.

Tolerances between ±0.05 mm and ±0.1 mm are standard, even on thicker materials.

Tip: When you select a fiber laser machine, always match fiber laser power to your required thickness and speed. This approach guarantees optimal performance and cost efficiency.

You achieve the best results with your fiber laser machine by mastering the right settings. Start by selecting the correct power level for the material and thickness you plan to cut. Adjust the focus position to match the surface of your workpiece. Set the cutting speed based on the thickness and type of metal. Fine-tune the assist gas pressure to clear molten material and prevent oxidation. Use the manufacturer’s recommended settings as a starting point, but always test and refine for your specific job.

To optimize fiber laser settings, monitor the kerf width and edge quality after each cut. If you see dross or rough edges, lower the speed or increase the power. For thin sheets, increase the speed and reduce power to avoid burning. Keep a log of your most effective settings for different materials. This practice saves time and ensures consistent results. When you optimize fiber laser settings, you reduce waste and improve productivity.

Tip: Use auto-focus features and pre-set libraries on advanced machines to quickly recall the best settings for each job.

Regular maintenance keeps your fiber laser machine running at peak performance. Clean optical components, such as lenses and mirrors, to maintain a clear laser path. Inspect the laser head alignment and electrical connections to catch issues early. Follow a strict maintenance schedule for cleaning, lubrication, and calibration. Pay attention to guide rails, as dust or debris can cause misalignment and affect cut quality. Maintain stable temperature and humidity in your workspace to support consistent cutting.

Here is a summary of essential maintenance practices:

| Maintenance Practice | Description |

|---|---|

| Clean Optical Components | Regularly clean lenses, mirrors, and other optical parts to maintain a clear and effective laser beam. |

| Maintain Regular Inspections | Conduct inspections to identify potential issues, including checking laser head alignment and electrical connections. |

| Regular Maintenance Schedule | Establish a schedule for cleaning, component replacement, lubrication, and calibration to prevent issues. |

| Regularly Inspect and Clean Guide Rails | Inspect and clean guide rails to prevent misalignment and ensure smooth movement of the laser head. |

| Calibration Procedures | Schedule regular calibration sessions to maintain precision and consistency in cutting performance. |

| Environmental Considerations | Maintain stable temperature and humidity levels to support consistent cutting performance. |

By following these steps, you extend the life of your machine and avoid costly downtime.

Your skills as an operator play a major role in achieving clean cuts and maximizing the capabilities of your fiber laser machine. Proper training helps you understand the equipment’s operating procedures and safety requirements. You must follow the recommended settings for each material and thickness. Regular equipment checks, part of your training, help you spot problems before they affect production.

Training ensures you know how to set up and adjust the machine for each job.

You must adhere to the correct settings to achieve the best cutting quality and thickness.

Routine checks and adjustments keep your machine performing at its best.

When you invest in skill development, you gain the confidence to optimize fiber laser settings for any project. This approach leads to higher productivity, better quality, and fewer errors.

When you push your fiber laser cutting machine to its maximum cutting thickness, you often notice changes in edge quality. The edges may show more dross, roughness, or even a slight taper. As you increase the cutting thickness, the laser beam must work harder to penetrate the material. This can lead to uneven edges, especially if the material has high reflectivity or inconsistent composition. You might see more burrs or a wider heat-affected zone. These issues become more pronounced as you approach the maximum for each material. To maintain the best edge quality, you should regularly check your optics, keep your assist gas clean, and fine-tune your focus settings. Using the correct gas type and pressure also helps you achieve smoother edges, even at the upper end of your cutting thickness range.

Tip: If you notice increased dross or roughness, slow down your cutting speed slightly and check your nozzle alignment. Small adjustments can make a big difference in edge quality at maximum thickness.

Cutting at maximum thickness means you must accept slower speeds. The thicker the material, the more energy and time your fiber laser cutting system needs to complete the cut. For example, when you cut ¾” carbon steel with a 2 kW laser, you reach speeds of about 22 inches per minute. With a 4 kW laser, you can increase that to 30 inches per minute. With a 3 kW fiber laser, you can cut up to 1” steel, but you will see a significant drop in speed compared to thinner materials.

| Laser Power | Material Thickness | Cutting Speed (inches/minute) | Piercing Time (seconds) |

|---|---|---|---|

| 2 kW | ¾” carbon steel | 22 | 20 |

| 4 kW | ¾” carbon steel | 30 | 2 |

| 3 kW | Up to 1” steel | N/A | N/A |

You must plan your workflow with these speed limitations in mind. When you operate at the maximum cutting thickness, you should expect longer cycle times. To offset this, use features like auto-focus heads and stable machine frames, which help you maintain quality without sacrificing too much productivity.

Material distortion becomes a real concern as you approach the maximum cutting thickness. The intense heat from the laser can cause warping, increased taper, or even incomplete cuts. You may also encounter problems if you use materials with high reflectivity or improper thickness. Inconsistent power output, often caused by fluctuations in your power supply or issues with the laser tube, can make these problems worse. Sudden drops in power may disrupt your cut, leaving you with incomplete or uneven results.

To minimize distortion, you should:

Use materials within the recommended cutting thickness range for your machine.

Regularly calibrate your fiber laser cutting system to ensure stable power output.

Inspect your power supply and perform routine maintenance to prevent sudden power drops.

Adjust your cutting parameters to match the material and thickness.

By following these steps, you reduce the risk of distortion and ensure your cuts remain precise, even at the maximum thickness your machine can handle.

When you cut materials at or near the maximum thickness with your 3000W fiber laser, you may encounter challenges that affect cut quality and consistency. Effective troubleshooting helps you maintain productivity and achieve the best results. Here are proven steps you can follow to resolve common issues:

Check the Laser Output

Begin by examining the laser beam. Make sure the spot appears circular and aligns with the center of the nozzle. If the spot looks distorted or off-center, you may see uneven cuts or incomplete penetration.

Inspect the Optical System

Look for dust, debris, or cracks on the lens and mirrors. Even a small amount of contamination can scatter the laser beam and reduce cutting power. Clean or replace optical components as needed to restore performance.

Adjust Cutting Parameters and Gas Purity

Review your cutting speed, power, and assist gas settings. If you notice rough edges or incomplete cuts, try lowering the speed or increasing the gas purity. High-quality nitrogen or oxygen helps you achieve cleaner edges, especially on thick materials.

Control Laser Power and Use Short Pulses

To prevent metal deformation, adjust the laser power or switch to short pulse mode. This approach reduces heat buildup and minimizes warping, especially when working with sensitive metals.

Slow Down Cutting Speed for Difficult Cuts

If your machine fails to cut through the material, reduce the cutting speed. Slower speeds give the laser more time to penetrate thick sections and improve the chance of a complete cut.

Clean or Replace Mirrors and Focusing Lens

Dirty or damaged mirrors and lenses can weaken the laser beam. Regularly clean these parts and replace them if you see signs of wear or contamination.

Align the Optical Path and Focus

Make sure the laser beam is concentric with the nozzle. Adjust the focus to match the material thickness. Proper alignment ensures consistent energy delivery and smooth edges.

Polish Reflective Surfaces Before Cutting

For metals like copper and aluminum, polish the surface before cutting. This step reduces reflectivity and helps the laser energy absorb more efficiently.

Maintain the Nozzle and Adjust Gas Pressure

Clean the nozzle regularly to prevent blockages. Adjust the gas pressure to match the material and thickness. Proper gas flow removes molten metal and keeps the cut clean.

Tip: Keep a troubleshooting log. Record the issues you encounter and the solutions that work. This habit helps you solve problems faster and improves your overall cutting process.

By following these steps, you can quickly identify and fix most problems that arise when cutting at maximum thickness. Consistent maintenance and careful adjustments keep your 3000W fiber laser running smoothly and ensure high-quality results on every job.

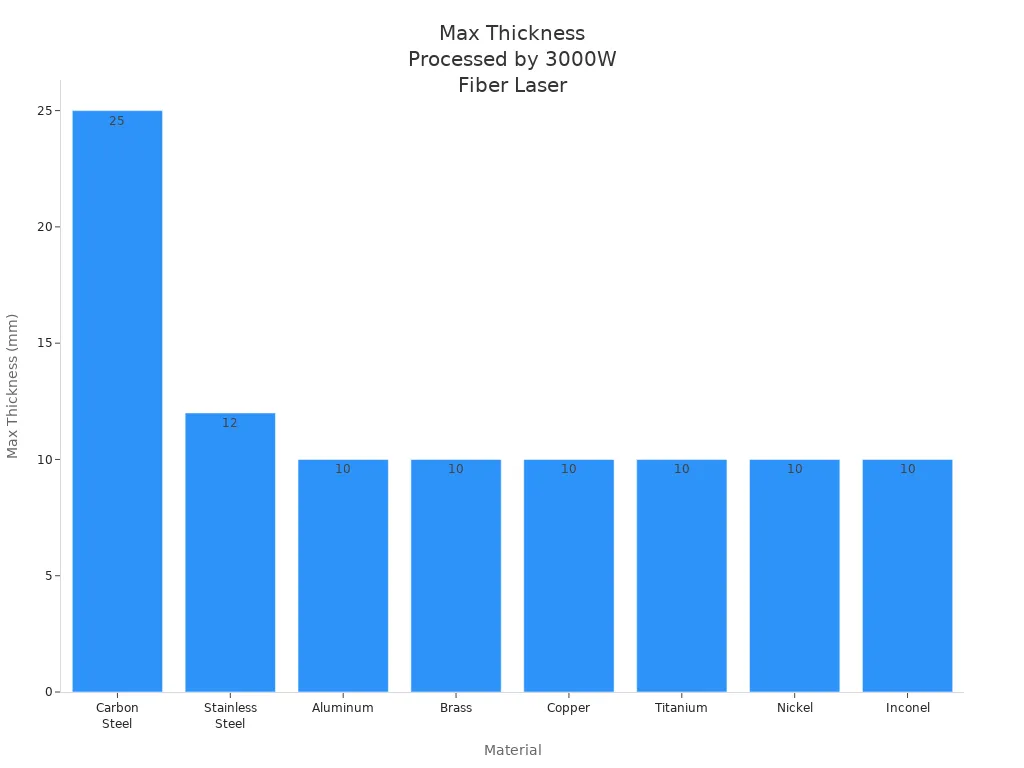

You work in an industry where precision and efficiency matter. The automotive sector relies on fiber laser machines to deliver consistent results across a wide range of materials. You often need to cut carbon steel, stainless steel, aluminum, brass, copper, titanium, nickel, and Inconel. Each material requires a specific approach to achieve the desired cutting thickness and quality. The 3000W fiber laser machine gives you the flexibility to handle both thin and thick sheets, making it ideal for everything from prototyping to mass production.

| Material | Maximum Thickness |

|---|---|

| Carbon Steel | Up to 25mm |

| Stainless Steel | Up to 12mm |

| Aluminum | Up to 10mm |

| Brass | Up to 10mm |

| Copper | Up to 10mm |

| Titanium | Up to 10mm |

| Nickel | Up to 10mm |

| Inconel | Up to 10mm |

You use fiber laser cutting to create intricate shapes and detailed designs for automotive components. This process ensures high quality and repeatability, which are essential for safety and performance. The maximum cutting thickness for each material allows you to produce everything from body panels to engine parts. You benefit from fast processing speeds and minimal waste, which help you stay competitive in a demanding market.

You face strict requirements in the aerospace industry. Every component must meet tight tolerances and pass rigorous inspections. Fiber laser machines help you achieve these goals by providing precise control over cutting thickness and edge quality. You often work with advanced materials such as titanium, Inconel, and high-grade aluminum. The maximum cutting thickness for these materials typically reaches up to 10mm, which covers most aerospace applications.

You rely on fiber laser power to cut lightweight structures, brackets, and panels. The process delivers clean edges and reduces the risk of material distortion. You can switch between different materials quickly, which supports rapid prototyping and short production runs. The quality of each cut ensures that your parts fit perfectly and perform reliably in critical environments.

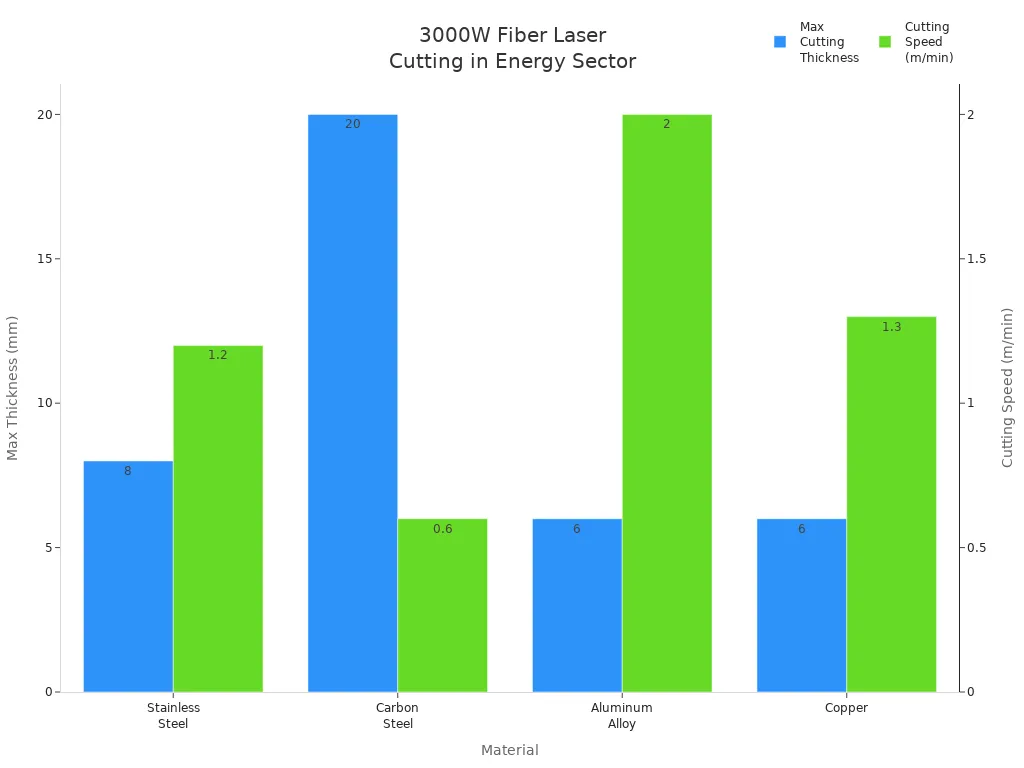

You support the energy sector by processing materials for solar frames, wind turbine components, and storage tanks. The 3000W fiber laser machine allows you to cut stainless steel up to 8mm, carbon steel up to 20mm, aluminum alloy up to 6mm, and copper up to 6mm. You achieve these results while maintaining high quality and efficient workflow.

| Material | Maximum Cutting Thickness | Cutting Speed |

|---|---|---|

| Stainless Steel | 8mm | 1.2 m/min |

| Carbon Steel | 20mm | 0.55-0.65 m/min |

| Aluminum Alloy | 6mm | 2 m/min |

| Copper | 6mm | 1.3 m/min |

You use fiber laser cutting to process thick and thin materials for a variety of energy applications. The process ensures that each cut meets industry standards for quality and durability. You benefit from the ability to handle large sheets and complex shapes, which streamlines your production and reduces costs.

Guangdong Jinan Pioneer CNC Technology Co., Ltd stands out as a leading manufacturer of fiber laser machines. You gain access to advanced technology, customization options, and reliable support for all your industrial applications.

You operate in a fast-paced environment where versatility and efficiency drive your success. Fabrication shops demand equipment that adapts to a wide range of projects, from custom prototypes to high-volume production runs. A 3000W fiber laser machine gives you the flexibility to handle diverse materials and thicknesses with precision.

You often work with carbon steel, stainless steel, aluminum, and copper. Each job may require different thicknesses, so you need a machine that transitions smoothly between tasks. With a 3000W fiber laser, you cut carbon steel up to 20mm, stainless steel up to 10mm, and aluminum or copper up to 6mm. For thinner sheets, you achieve clean cuts down to 0.5mm. This range covers most fabrication needs, whether you build structural frames, enclosures, brackets, or decorative panels.

Tip: Use auto-focus and quick-change settings to switch between materials and thicknesses without losing productivity.

You benefit from high cutting speeds and consistent edge quality. This performance reduces the need for secondary finishing, saving you time and labor costs. You also maintain tight tolerances, which is essential when fabricating parts that must fit together perfectly.

Here are common applications you handle in a fabrication shop:

Custom metal signage and artwork

HVAC ductwork and enclosures

Machine guards and safety covers

Furniture frames and fixtures

Agricultural equipment components

A 3000W fiber laser machine supports both sheet and tube cutting. You process round, square, or rectangular tubes for handrails, supports, and frames. This capability expands your service offerings and attracts more clients.

| Material | Typical Thickness Range (mm) | Common Applications |

|---|---|---|

| Carbon Steel | 1 – 20 | Frames, brackets, panels |

| Stainless Steel | 1 – 10 | Enclosures, guards, covers |

| Aluminum | 1 – 6 | Signs, fixtures, panels |

| Copper | 1 – 6 | Electrical parts, accents |

You rely on robust machine construction for stability during long shifts. Guangdong Jinan Pioneer CNC Technology Co., Ltd provides fiber laser machines engineered for industrial use. You gain access to advanced features like water-cooled lasers, heavy-duty frames, and intuitive controls. These advantages help you deliver quality results on every project.

Note: Regular maintenance and operator training ensure your machine performs at its best, even in demanding shop environments.

You stay competitive by investing in technology that adapts to your workflow. A 3000W fiber laser machine positions your fabrication shop for growth and success in today’s market.

You gain reliable cutting thickness across a range of metals with a 3000W fiber laser cutting machine. Review the table below for typical cut ranges:

| Material | Cutting Thickness Range |

|---|---|

| Carbon Steel | 0.5mm - 20mm |

| Stainless Steel | 0.5mm - 10mm |

| Aluminum Alloy | 0.5mm - 8mm |

| Copper | 0.5mm - 6mm |

Machine quality, process parameters, and proper optimization ensure you achieve precise cut results. For demanding applications, consult manufacturers to select the right fiber laser cutting solution for your specific cutting thickness needs.

You can cut carbon steel, stainless steel, aluminum, copper, brass, and some alloys. The machine handles both sheet and tube formats, making it suitable for a wide range of industrial applications.

Assist gas removes molten metal and cools the cut zone. Nitrogen produces clean, oxidation-free edges. Oxygen increases cutting speed and thickness for carbon steel. Proper gas selection ensures optimal edge quality and cutting efficiency.

You should clean optics weekly, inspect guide rails monthly, and calibrate the system quarterly. Regular maintenance prevents downtime and extends machine life. Always follow the manufacturer’s recommended schedule for best results.

Yes, you can cut copper and aluminum with a 3000W fiber laser. Use specialized optics and proper settings to handle high reflectivity. Nitrogen assist gas helps achieve clean, burr-free edges on these metals.

You should slow down the cutting speed, use the correct assist gas, and ensure precise focus. Regularly clean optics and maintain nozzle alignment. These steps help you produce smooth, high-quality edges even at maximum thickness.

Always wear protective eyewear, follow lockout procedures, and keep the work area clear. You must receive proper training and understand emergency shutdown protocols. Safety measures protect you and your team during operation.

Use auto-focus features and pre-set cutting parameters. Advanced machines let you store settings for various materials and thicknesses. This approach saves time and ensures consistent results when changing jobs.

Yes, your skill level directly affects cut quality and productivity. Proper training helps you set optimal parameters, perform routine checks, and troubleshoot issues. Skilled operators maximize machine capabilities and deliver superior results.