Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

Choosing between a CO2 laser cutter and a FIBER LASER MACHINE depends on your materials, budget, and application. You see significant differences in how each technology performs. Fiber lasers excel at cutting reflective metals, while CO2 lasers work best for non-metals. Maintenance costs for fiber lasers remain low, typically $200-400 per year, compared to $1,000-2,000 for CO2 systems. The table below shows how market adoption varies:

| Technology | Market Size (2024) | Projected Market Size (2033) | CAGR (2026-2033) |

|---|---|---|---|

| CO2 Laser Cutters | USD 1.32 Billion | USD 2.18 Billion | 6.25% |

Consider your specific requirements to determine which laser cutter delivers the best results for your business.

When you compare a fiber laser to a co2 laser, you notice clear differences in how each machine operates and what materials they handle best. Fiber laser machines use an optical fiber doped with rare-earth elements as the gain medium. This design gives you high efficiency and excellent beam quality. You can cut metals with speed and precision, making fiber laser technology a top choice for industries like automotive, telecommunications, and advanced manufacturing.

A co2 laser, on the other hand, uses a gas mixture of carbon dioxide, nitrogen, and helium. This setup produces a longer wavelength, which works well for cutting and engraving non-metal materials such as wood, acrylic, glass, and fabric. If your business focuses on signage, packaging, or creative arts, a co2 laser offers reliable performance for these applications.

To help you see the main differences at a glance, check the table below:

| Feature | Fiber Laser | CO2 Laser |

|---|---|---|

| Gain Medium | Optical fiber with rare-earth elements | Gas mixture (CO2, N2, He) |

| Wavelength | 1064 nm (near-infrared) | 10.6 µm (far-infrared) |

| Efficiency | Over 90% | 5-10% |

| Beam Quality | Excellent, precise cuts | Good, less precise |

| Material Compatibility | Metals, plastics, ceramics | Wood, acrylic, glass, fabric |

| Maintenance | Minimal, solid-state | Higher, needs gas refills and mirror care |

| Cutting Speed | Fast, high precision | High speed, less precision |

You benefit from understanding how each laser technology impacts your workflow and results. Fiber laser machines use a solid-state source and deliver the laser beam through a flexible fiber optic cable. This method allows for a smaller spot size and tighter cuts, which means you achieve cleaner edges and finer details on metal parts. The high energy efficiency of fiber laser systems also reduces your operating costs over time.

A co2 laser relies on a gas-filled tube and directs the beam using mirrors and lenses. This approach works best for non-metals, giving you smooth cuts on organic materials. However, you need to perform regular maintenance, such as replacing gas and cleaning optics, to keep your co2 laser running at peak performance.

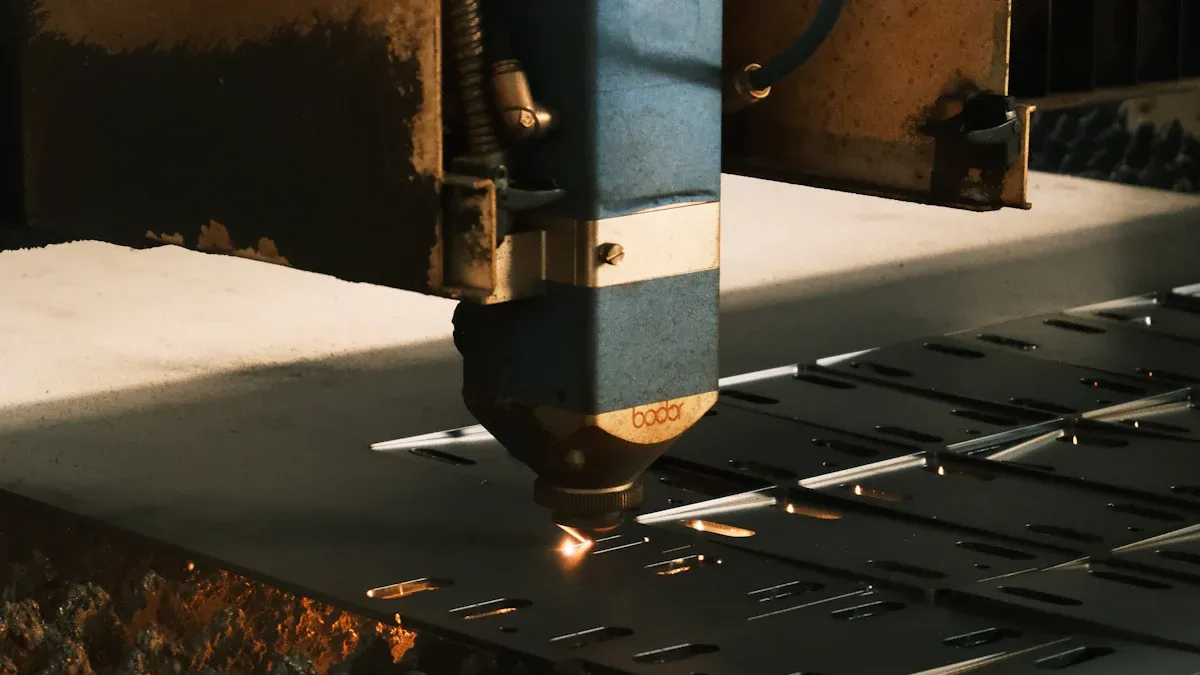

If you operate in industries that demand high precision and speed for metal processing, a fiber laser machine stands out as the superior choice. Guangdong Jinan Pioneer CNC Technology Co., Ltd leads the market with advanced fiber laser solutions. Their machines offer robust performance, minimal maintenance, and the flexibility to handle both sheet and tube cutting. By choosing a fiber laser from a trusted manufacturer, you position your business for greater productivity and long-term value.

When you need to cut metals with high efficiency and accuracy, a fiber laser machine stands out as the top choice. You benefit from exceptional processing speeds and the ability to handle a wide range of metal thicknesses. The fiber laser delivers a focused beam that allows you to achieve a smoother cut edge, even on reflective metals like stainless steel, aluminum, brass, and copper.

You can see the impressive performance of fiber laser machines in the following table, which shows the maximum cutting speed for different sheet thicknesses:

| Thickness Category | Cutting Speed (IPM) |

|---|---|

| Thinner Sheets | Up to 3,000 IPM |

| Thicker Sheets | Up to 1,500 IPM |

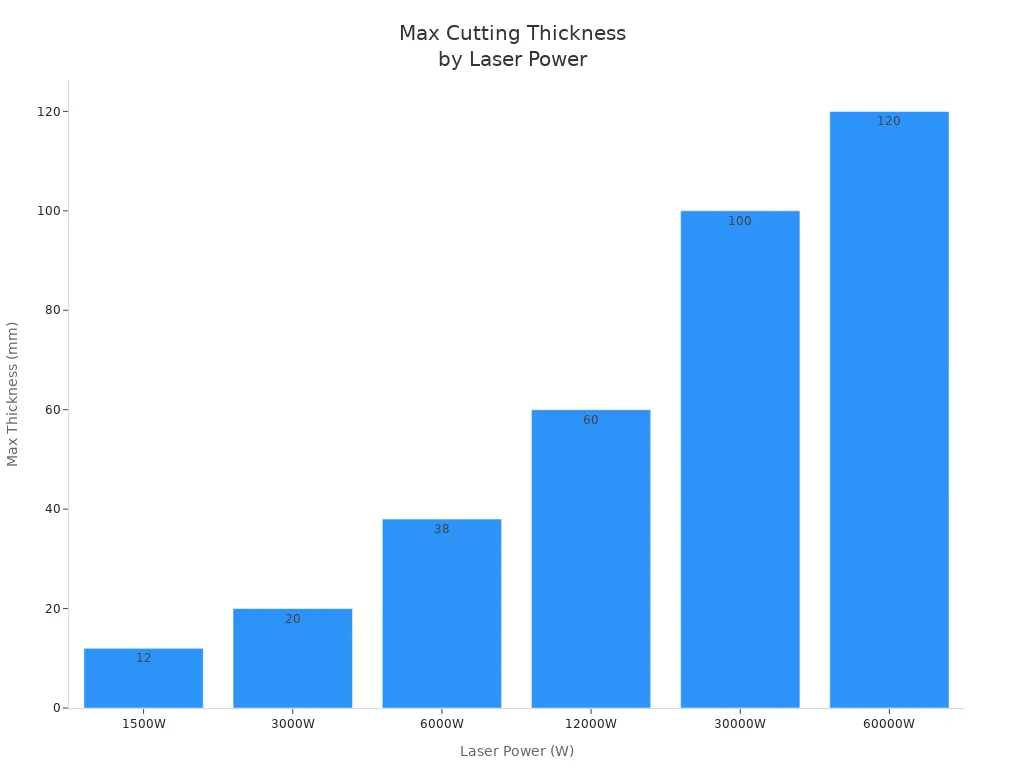

The power of your fiber laser machine directly impacts the maximum thickness you can cut. Here is a breakdown of the capabilities by laser power:

| Laser Power | Max Carbon Steel Thickness |

|---|---|

| 1500W | 6mm – 12mm |

| 3000W | Up to 20mm |

| 6000W | 25mm – 38mm |

| 12000W | 50mm – 60mm |

| 30000W | 70mm – 100mm+ |

| 60000W | Up to 120mm+ |

You achieve not only high cutting speed but also remarkable cut precision. The advanced technology in Guangdong Jinan Pioneer CNC Technology Co., Ltd's fiber laser machines ensures you get a smoother cut edge with minimal burrs. You can process both sheet and tube metals, making these machines ideal for industries such as automotive, energy, and heavy equipment manufacturing. The robust design and automation features help you maintain consistent performance and high productivity.

If your focus is on non-metal materials, a CO2 laser offers you excellent versatility. You can cut a wide variety of materials, including:

Wood products

Paper

Plastic

Rubber

Acrylic

Bamboo

Marble

Glass

Wine bottles

CO2 lasers provide a smoother cut edge on organic and synthetic materials. You can select the right power level for your application, as shown below:

| Power Level | Recommended Thickness | Applicable Materials |

|---|---|---|

| Low Power | 0.5mm to 6mm | Paper, cardboard, thin plastics, fabrics |

| Medium Power | 6mm to 18mm | Thicker plastics, wood, acrylic |

| High Power | 18mm to 30mm | Metals, dense materials |

You can reach a maximum cutting speed of 50,000mm/min with a 100W CO2 laser. For acrylic, you can cut up to 20mm thick, and for wood, up to 18mm at higher power settings. When you work with thicker materials, you need to slow down the cutting speed to prevent heat buildup and maintain a smoother cut edge. This approach helps you avoid scorching and ensures the quality of your finished product.

You want your finished parts to meet strict standards for accuracy and appearance. Fiber laser machines give you a finer, more focused beam, which results in higher cut precision and a smaller kerf width. You can achieve a smoother cut edge on metals, especially when working with thin sheets. This level of detail is essential for industries that require tight tolerances and clean finishes.

CO2 lasers excel at producing a smoother cut edge on non-metals. You notice that the surface edges are often cleaner and more polished compared to other cutting methods. The following table summarizes the differences in precision and cut quality:

| Laser Type | Precision | Cut Quality | Best For |

|---|---|---|---|

| Fiber Laser | High precision, especially with thin materials | Finer, more focused beam with smaller kerf width | Metals, particularly reflective types like stainless steel |

| CO2 Laser | Versatile for a wider range of materials | Smoother edges on cut pieces | Thicker non-metals like wood, acrylic, glass, and textiles |

You can rely on fiber laser machines for metals, including stainless steel, aluminum, brass, and copper. For non-metals such as wood, acrylic, glass, paper, textiles, and some plastics, CO2 lasers remain the preferred choice. When you need a smoother cut edge and high cut precision, both technologies deliver excellent results in their respective domains.

Guangdong Jinan Pioneer CNC Technology Co., Ltd's fiber laser machines provide you with advanced automation, consistent performance, and the ability to achieve a smoother cut edge on a wide range of metals. You can trust these machines to deliver the quality and reliability your business demands.

You gain a significant advantage when you choose a fiber laser for metal processing. This technology offers outstanding material compatibility with a wide range of metals. You can cut, engrave, or mark ferrous metals like mild steel and stainless steel. You also process non-ferrous metals such as aluminum alloys, brass, and copper. Fiber laser machines deliver precise results on metal sheets and tubes, making them ideal for industrial manufacturing.

You benefit from high efficiency and speed, especially when working with reflective metals. Fiber laser systems handle stainless steel and aluminum with ease. You achieve clean edges and minimal burrs, which reduces your finishing time. You also use fiber laser machines for marking and engraving serial numbers, barcodes, and logos on metal components. This capability supports traceability and quality control in your production line.

Tip: You should consider the thickness of your materials. Fiber laser machines typically cut metals from 0.1mm up to 25mm. For thicker metals, you may need to evaluate alternative cutting technologies.

Here is a quick overview of materials you can process with a fiber laser:

Mild steel

Stainless steel

Aluminum alloys

Brass

Copper

Titanium

Polymers (such as acrylic and polycarbonate)

You should note that highly reflective metals like copper and polished aluminum may require specific settings to maximize efficiency and safety. Transparent materials, such as certain glasses and clear plastics, need special wavelengths for effective processing. Fiber laser machines excel in industrial applications, including automotive parts, energy equipment, and electronics manufacturing.

You achieve excellent results when you use a co2 laser for non-metal materials. This technology offers broad material compatibility with organic and synthetic substances. You can cut and engrave wood, acrylic, paper, fabric, and glass. Co2 laser machines provide smooth edges and detailed finishes, which are essential for commercial and creative industries.

You find co2 laser systems especially useful for producing signage, packaging, and decorative items. You process acrylic for LED lights, medals, jewelry, and advertising signs. You cut wood to create architectural models, clocks, and musical instruments. You use co2 laser machines to engrave paper for art projects, packaging boxes, and invitation cards. You also cut fabric for handbags and clothing in the fashion industry.

Here is a table showing common non-metal materials and their typical applications:

| Material | Application Examples |

|---|---|

| Acrylic | LED lights, medals, jewelry, signs |

| Wood | Clocks, models, musical instruments |

| Paper | Art works, packaging, invitations |

| Fabric | Handbags, clothing, accessories |

| Glass | Decorative panels, bottles |

| Rubber | Gaskets, stamps |

| Marble | Inlays, decorative tiles |

You can process thicker non-metallic materials with a co2 laser, often up to 30mm. You achieve high-quality cuts and engravings, which enhance your product value and customer satisfaction.

You maximize your productivity when you match the right laser technology to your application. Fiber laser machines serve a wide range of industrial uses. You cut, mark, weld, clean, texture, and drill metal components. You use fiber laser systems for manufacturing automotive parts, energy storage devices, and electronic enclosures. You also apply fiber laser technology in telecommunications and medical device production.

You rely on co2 laser machines for commercial and creative applications. You produce signage, packaging, and decorative items with precision. You use co2 laser systems to engrave logos, create custom gifts, and manufacture fashion accessories. You also process organic materials for architectural models and art installations.

Here are typical use cases for each technology:

Fiber laser:

Cutting and welding metal sheets and tubes

Marking serial numbers and barcodes

Cleaning and texturing surfaces

Drilling precise holes in metal parts

Manufacturing automotive, energy, and electronics components

CO2 laser:

Cutting and engraving wood, acrylic, and fabric

Producing signage and advertising displays

Creating packaging boxes and invitations

Manufacturing decorative items and art works

Processing glass and marble for custom designs

You should evaluate your material compatibility needs before investing in a laser system. Fiber laser machines offer superior performance for metals, while co2 laser machines excel with non-metals. You optimize your workflow and control your cost by selecting the right technology for your business.

When you evaluate laser cutting machines, you notice a significant difference in up-front cost between fiber laser and CO2 laser systems. Fiber laser machines require a higher initial investment, reflecting their advanced technology and industrial-grade capabilities. CO2 laser cutters offer a lower entry point, making them accessible for smaller businesses or those focused on non-metal applications.

| Laser Cutter Type | Initial Investment Cost |

|---|---|

| Fiber Laser | $250,000 to over $2 million |

| CO2 Laser | Starting at $15,000 |

You should consider the up-front cost as a key factor in your purchasing decision. Fiber laser machines deliver greater versatility and productivity for metal processing, which justifies their higher price for many industrial users. CO2 lasers provide a budget-friendly solution for creative and commercial projects involving non-metals.

Operating costs play a major role in your long-term planning. Fiber laser machines stand out for their energy efficiency. You benefit from lower electricity bills and reduced gas consumption. CO2 lasers consume more power and require regular gas refills, which increases your daily operating expenses.

| Laser Type | Energy Efficiency (%) | Power Requirement (kW) | Daily Operating Cost ($) |

|---|---|---|---|

| Fiber Laser | 30-50 | 6-10 | 5-8 |

| CO2 Laser | 10-15 | 15-20 | 10-20 |

Fiber lasers use less energy, which lowers your cost of ownership.

CO2 lasers need more power and gas, resulting in higher operating costs.

You save money over time with fiber laser machines due to their efficient design.

Tip: If you run high-volume production, the energy savings from fiber lasers can add up quickly, offsetting the higher up-front cost.

Maintenance requirements affect your workflow and overall cost. Fiber laser machines feature a solid-state design, which means fewer moving parts and less wear. You spend less time and money on repairs and upkeep. CO2 lasers need regular inspections, calibration, and gas refills. You also replace laser tubes every few years, which adds to your maintenance cost.

| Aspect | CO2 Laser Cutter | Fiber Laser Cutter |

|---|---|---|

| Annual Parts and Repairs | $500 to $3,000 | $200 to $1,000 |

| Annual Maintenance Costs | $1,000 to $3,000 | $500 to $2,000 |

| Laser Tube Replacement | Every 1-2 years for $1,000 to $5,000 | N/A |

| Maintenance Requirements | Regular inspections, calibration, gas refills | Fewer maintenance requirements, longer lifespan |

| Energy Consumption | 1-3 kW, $0.10 to $0.60 per hour | 1-60 kW, $0.90 to $52 per hour |

You gain reliability with fiber laser machines. These systems operate for thousands of hours without major issues. Their performance remains stable, which supports your business goals and reduces downtime. The optical fiber delivery system is durable, and you avoid the hassle of mirror alignment or gas management. Fiber lasers can run for over 100,000 hours, making them a smart investment for long-term value.

Note: When you factor in energy savings, reduced maintenance, and longer lifespan, fiber laser machines offer a lower total cost of ownership for industrial users.

You want your laser cutting process to deliver fast results and high throughput. Fiber laser machines give you a clear advantage in industrial environments. When you cut 1mm stainless steel, fiber lasers reach speeds up to 40 meters per minute. CO2 lasers, in comparison, achieve only 20 meters per minute for the same material. If you work with thin gauge metals, fiber lasers can operate three times faster than CO2 systems. This speed boost means you complete more jobs in less time.

Ultrahigh-power fiber lasers push productivity even further. For example, increasing the power from 15 kW to 40 kW can raise cutting speed by 280% for 12-mm-thick carbon steel. You avoid slowdowns and bottlenecks, especially when you need continuous production. Fiber lasers also use 30% less energy on average compared to CO2 lasers. This improvement in energy efficiency helps you lower your operating costs and supports sustainable manufacturing.

The table below highlights key differences in workflow efficiency and productivity:

| Feature | Fiber Laser | CO2 Laser |

|---|---|---|

| Cutting Speed | Up to 40 m/min for 1mm steel | Up to 20 m/min for 1mm steel |

| Efficiency | 30% less energy consumption | Higher energy consumption |

| Maintenance | Longer lifespan (100k+ hours) | Frequent tube replacements |

| Suitability | Best for metals | Best for non-metals |

| Production Environment | High-speed production | Slower production |

You see that fiber laser machines offer superior energy efficiency and faster turnaround. These advantages help you meet tight deadlines and scale your business.

Modern fiber laser machines come equipped with advanced automation features that streamline your workflow. You can operate dual 24-inch touchscreen controls for easy management. Smart automation systems include automatic nozzle changers with quick-connect technology. These features reduce manual intervention and minimize downtime.

You can also add optional material handling modules to your setup. These modules allow you to scale your production as your business grows. Smart software solutions help you optimize cutting paths and nest parts efficiently. You benefit from:

Dual-platform systems for simultaneous loading and unloading

Automatic nozzle changers for quick setup

Touchscreen controls for intuitive operation

Material handling modules for increased scalability

Smart nesting software for efficient material use

Tip: Automation features in fiber laser machines help you save time, reduce errors, and boost overall energy efficiency. You can focus on quality and productivity while the system handles repetitive tasks.

Fiber laser machines from leading manufacturers, such as Guangdong Jinan Pioneer CNC Technology Co., Ltd, integrate these automation options to maximize your efficiency. You achieve consistent results and maintain high output, even in demanding production environments.

You expect outstanding quality when you invest in a laser cutting machine. Fiber laser machines deliver high precision and consistent quality on metal parts. You notice that the cut edge quality stands out, especially on stainless steel, aluminum, and copper. The focused beam of a fiber laser produces a narrow kerf and minimal heat-affected zone. This results in a clean, smooth edge with little to no post-processing required. You achieve high precision cuts on thin and thick metals alike, which is essential for industries that demand tight tolerances.

When you work with cosmetically critical materials, such as vinyl-coated stainless steel, you may see some challenges with fiber lasers. The coating can affect the quality of the cut edge, so you need to adjust your settings or consider alternative methods for the best results. For most metals, fiber lasers provide superior quality and high precision, making them the preferred choice for industrial applications.

CO2 laser machines also offer reliable quality, especially on non-metal materials. You see smooth, polished edges on wood, acrylic, and glass. The longer wavelength of a CO2 laser interacts well with organic materials, giving you excellent quality for signage, packaging, and decorative products. When you cut thicker non-metals, CO2 lasers maintain quality, but you may need to slow down the process to avoid burning or charring.

You can compare the cut edge quality of both technologies:

Fiber lasers deliver high precision and clean edges on metals.

CO2 lasers provide smooth, polished edges on non-metals.

Fiber lasers may face challenges with certain coated materials, which can impact the quality of the cut edge.

You should always match your machine to your material to achieve the highest quality.

You rely on repeatability to ensure every part meets your standards. Fiber laser machines excel in this area, offering high precision and consistent quality across large production runs. You benefit from advanced motion control systems and stable beam delivery. This allows you to achieve repeatability of ±0.0007" (0.02 mm) and precision of ±0.001" (0.03 mm). You can trust that each cut will match the last, which is critical for industries like automotive, aerospace, and electronics.

CO2 laser machines also provide reliable repeatability, especially for thicker materials. You see consistent quality on wood, acrylic, and other non-metals. However, fiber lasers set the benchmark for high precision and repeatability, especially when you need tight tolerances and clean finishes.

You can summarize the performance of both machines:

Fiber laser machines deliver high precision and repeatability, making them ideal for demanding industrial tasks.

CO2 laser machines offer reliable quality for non-metals, with good repeatability on thicker materials.

Fiber lasers achieve tighter tolerances and cleaner cuts compared to older technologies.

Guangdong Jinan Pioneer CNC Technology Co., Ltd enhances your results with advanced high precision features:

Five Axis Cutting Head: You gain high dynamics and accuracy. The responsive servo system maintains the correct distance from the workpiece. Non-contact distance sensing and automatic compensation ensure consistent quality. Collision protection allows for quick resets, reducing downtime.

Off-line Programming Software: You use virtual simulation to convert digital models into machining programs. This software optimizes cutting paths and speeds, improving operational efficiency and quality.

You achieve high precision and outstanding quality with every cut. These features help you maintain a competitive edge in your industry.

You see fiber laser and CO2 laser cutters used across many industries. Each technology brings unique strengths to your production floor. Fiber laser machines excel in environments where you need to process metals with speed and precision. You find them essential in automotive, aerospace, and advanced manufacturing. You use fiber lasers to cut, weld, engrave, and mark metal parts. These machines help you create body panels, chassis, and structural components for vehicles. Aerospace manufacturers rely on fiber lasers for lightweight metal parts that require tight tolerances. In metal fabrication shops, you produce frames, brackets, enclosures, and custom components with fiber laser technology.

CO2 laser cutters serve industries that work with non-metal materials. You use them to cut wood, acrylic, fabric, and glass. Signage companies depend on CO2 lasers for crisp lettering and intricate designs. Packaging manufacturers use CO2 lasers to create custom boxes and decorative elements. You also see CO2 lasers in creative industries, where artists and designers shape organic materials into unique products.

Here is a comparison of common industrial applications:

| Laser Type | Common Applications | Industries |

|---|---|---|

| Fiber Laser | Cutting, welding, engraving, marking metal parts | Automotive, manufacturing, aerospace, metal fabrication |

| CO2 Laser | Cutting non-metal materials (wood, acrylic, fabric) | Signage, packaging, creative arts, non-metal industries |

Tip: You maximize efficiency and quality by choosing the right laser cutter for your industry’s materials and production needs.

You benefit from laser technology in commercial and hobby settings as well. Fiber laser machines offer you the ability to engrave serial numbers, barcodes, and logos on metal products. Small businesses use fiber lasers to create custom metal signage, jewelry, and promotional items. You can cut stainless steel, carbon steel, aluminum, brass, copper, and galvanized sheet with high precision.

CO2 laser cutters give you flexibility for creative projects. You design and produce personalized gifts, decorative panels, and art pieces. Hobbyists use CO2 lasers to craft wooden models, acrylic ornaments, and fabric accessories. You can engrave glassware, rubber stamps, and marble tiles for unique home décor or business branding.

You see fiber lasers and CO2 lasers supporting a wide range of applications:

Fiber lasers:

Metal signage and custom jewelry

Industrial part marking and engraving

Small-scale metal fabrication

CO2 lasers:

Personalized gifts and crafts

Decorative wood and acrylic panels

Fashion accessories and textile art

Note: You unlock new possibilities for your business or hobby by selecting a laser cutter that matches your creative vision and material requirements.

When you evaluate fiber laser machines, you notice several strengths that make them attractive for industrial use. You achieve high efficiency and precision, especially when working with metals. Fiber lasers deliver finer cuts and faster processing speeds, which help you boost productivity. You also benefit from lower maintenance needs and longer machine lifespan, often exceeding 100,000 hours. However, you should consider the higher initial investment and the limited versatility with non-metal materials.

Advantages of Fiber Laser Machines:

You achieve greater energy efficiency, reducing operating costs.

You produce more precise and intricate cuts, ideal for detailed metalwork.

You experience faster marking and engraving speeds on metals.

You benefit from a long service life, minimizing downtime.

You spend less on maintenance due to the solid-state design.

Disadvantages of Fiber Laser Machines:

You pay a higher upfront cost compared to CO2 lasers.

You face limitations when working with thicker materials or non-metals.

You may need specialized settings for certain reflective metals.

Tip: If your business focuses on metal processing and values speed, precision, and reliability, fiber laser machines offer a strong return on investment.

CO2 laser machines provide you with versatility across a wide range of materials. You can cut and engrave wood, acrylic, glass, and textiles with smooth edges. The lower initial cost makes CO2 lasers accessible for small businesses and creative projects. You also find CO2 lasers perform better on thicker materials, delivering cleaner cuts. However, you should expect higher energy consumption and more frequent maintenance, including realignment and gas tube replacement.

Advantages of CO2 Laser Machines:

You pay less for the initial purchase, making it budget-friendly.

You work with a broader selection of materials, including non-metals.

You achieve smoother cuts on thicker materials like wood and acrylic.

You enjoy flexibility for signage, packaging, and creative applications.

Disadvantages of CO2 Laser Machines:

You use more energy, increasing operating costs.

You spend more time and money on maintenance and repairs.

You produce less precise cuts compared to fiber lasers.

Note: If you need a machine for diverse materials or thicker non-metals, CO2 lasers provide reliable performance and flexibility.

You can use the following table to compare fiber laser and CO2 laser machines at a glance:

| Feature | Fiber Laser | CO2 Laser |

|---|---|---|

| Cost | Higher initial investment | Lower upfront cost |

| Efficiency | More energy-efficient | Less efficient |

| Precision | Finer, more accurate cuts | Less precise, rougher cuts |

| Versatility | Best for metals, limited non-metal capability | Wide range of materials, especially non-metals |

| Performance on Thick Materials | Less effective on thick materials (>5mm) | Better performance on thick non-metals |

| Maintenance | Lower maintenance, longer lifespan | Higher maintenance, frequent realignment |

| Best Use Cases | Industrial metal cutting, marking, engraving | Signage, packaging, creative non-metal work |

Choosing the right laser cutter depends on your materials, budget, and production goals. Use this comparison to guide your decision and maximize your investment.

Selecting the right laser cutter for your business requires a clear evaluation of your needs. You should focus on the materials you plan to process, your budget, and your production goals. The following table helps you compare key factors between fiber laser and CO₂ laser machines:

| Factor | Fiber Laser | CO₂ Laser |

|---|---|---|

| Absorption | High for metals | Low for metals |

| Efficiency | Over 40% conversion | 10–15% conversion |

| Maintenance Frequency | No alignment needed | Monthly alignment required |

| Tube Replacement | None | Every 2–3 years |

| Lifespan | 100,000 hours | 2,000–4,000 hours |

| Chiller Upkeep | Low | Medium |

| Application Suitability | Best for metals | Best for organics |

Tip: Review each factor in the table. Match your production requirements to the strengths of each laser type. This approach helps you avoid costly mistakes and ensures long-term satisfaction.

You maximize your investment when you align your needs with the right laser technology. Consider these important points:

Laser Technology: Choose fiber lasers for metals. Select CO₂ lasers for non-metals and organic materials.

Material Thickness: Assess the thickness of your materials. Higher wattage supports thicker cuts.

Laser Power: Opt for greater power if you need faster cutting or thicker materials. Remember, higher power increases costs.

Bed Size: Confirm that the cutting bed fits your typical material dimensions.

Software Compatibility: Ensure the machine works with your design software for smooth workflow.

Maintenance Costs: Factor in ongoing maintenance. Fiber lasers require less upkeep than CO₂ lasers.

Set a clear budget before you compare models.

Request quotes from several suppliers to find the best value.

Balance your production needs with your financial constraints.

Note: Consulting with manufacturers such as Guangdong Jinan Pioneer CNC Technology Co., Ltd gives you access to tailored solutions. You benefit from higher precision, reduced material waste, and faster production times. Their machines handle complex shapes and tight tolerances, helping you achieve superior results.

| Benefit | Description |

|---|---|

| Higher Precision | Achieves tight tolerances for perfect assembly. |

| Reduced Material Waste | Non-contact cutting minimizes waste. |

| Faster Production Times | Outpaces traditional methods, reducing lead times. |

| Versatility | Handles complex geometries and shapes with ease. |

You ensure the best outcome by matching your needs to the right laser type and working with trusted experts. This strategy supports your business growth and delivers consistent quality.

You face a choice shaped by your materials, budget, and production goals. Review the table below to compare essential features:

| Feature | CO2 Laser Cutters | Fiber Laser Cutters |

|---|---|---|

| Technology & Design | Uses gas mixture; larger and more complex | Solid-state; compact and robust |

| Material Compatibility | Best for non-metals (wood, acrylic) | Best for metals (steel, aluminum) |

| Cutting Speed | Slower on thin metals | Up to 3 times faster on thin metals |

| Energy Efficiency | 10-15% conversion efficiency | Up to 30% conversion efficiency |

| Maintenance | Higher maintenance due to gas and mirrors | Lower maintenance; fewer moving parts |

| Lifespan | 20,000 to 30,000 hours | Up to 100,000 hours |

Use the comparison and checklist to guide your decision. Reach out to trusted manufacturers for expert advice and product demonstrations. Focus on your specific requirements to select the best laser cutter for your business.

You can cut metals such as steel, stainless steel, aluminum, brass, and copper. Fiber lasers also work on some plastics and ceramics. You should use fiber lasers for industrial metal processing and marking tasks.

You achieve the best results on wood, acrylic, glass, fabric, and paper with a CO2 laser cutter. You should choose CO2 technology for creative, signage, and packaging applications involving non-metals.

You perform basic cleaning and checks every few months. Fiber laser machines require less frequent maintenance than CO2 lasers. You benefit from a longer lifespan and lower annual upkeep costs.

You can engrave metals and some plastics with a fiber laser. You achieve high precision and speed for serial numbers, barcodes, and logos. Fiber lasers excel at industrial marking tasks.

You expect a fiber laser cutter to last up to 100,000 hours. The solid-state design ensures durability and consistent performance. You minimize downtime and replacement costs.

You use automation features like dual platforms, smart software, and automatic nozzle changers to speed up workflow. Automation reduces manual tasks and errors, helping you boost output and efficiency.

You save more energy with a fiber laser cutter. Fiber lasers convert over 30% of input power to cutting energy. CO2 lasers use more electricity and require regular gas refills.

You can cut thick non-metals, such as wood and acrylic, up to 30mm with a CO2 laser. For thick metals, you should use a high-power fiber laser for better results.