Views: 0 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

Fiber Laser Cladding Machines are transforming industrial production. How are they changing the way we approach surface enhancement?

In today's manufacturing world, industries like aerospace, automotive, and chemical processing are increasingly turning to fiber laser cladding to improve the durability and efficiency of components. In this article, we’ll explore how these machines work, their benefits, and the industries they impact.

Fiber laser cladding involves using a high-powered laser beam to melt metal powder or wire onto the surface of a material. The molten material then bonds to the substrate, creating a dense, metallurgically bonded layer that significantly enhances the surface properties of the material. The precision of fiber laser cladding ensures that only specific areas are treated, providing efficient use of material and energy.

The process offers several key benefits:

High Precision: A fiber laser enables fine control over the material deposition, ensuring smooth, uniform coatings with minimal distortion.

Reduced Heat Impact: Unlike traditional methods, fiber laser cladding uses low heat input, preventing warping or cracks in the underlying substrate.

Enhanced Durability: The metallurgical bond formed between the cladding and the substrate increases resistance to wear, corrosion, and other environmental factors.

A fiber laser cladding machine typically consists of several critical components, each essential for the overall process:

Fiber Laser Unit: This generates the high-energy laser beam used to melt the cladding material. Fiber lasers are known for their high power output, excellent beam quality, and efficiency, contributing to the precision of the cladding process.

Intelligent Powder Feeder: This device delivers metal powder or wire to the substrate, ensuring even and controlled material deposition. It plays a vital role in ensuring the quality and uniformity of the cladding layer.

Chiller: A chiller regulates the temperature of the laser and the substrate, preventing overheating and maintaining process stability.

Control System: The control system coordinates the movement of the laser and the powder feeder, adjusting various parameters like scanning speed and laser power to achieve optimal results.

Each of these components plays a crucial role in ensuring the efficiency and precision that make fiber laser cladding machines so effective in industrial applications. Together, they enable the technology to offer repeatable and scalable results, making it an attractive choice for a wide range of industries.

| Component | Function |

|---|---|

| Fiber Laser Unit | Generates the high-energy laser beam required for melting the cladding material. |

| Intelligent Powder Feeder | Delivers metal powder or wire to the substrate for even material deposition. |

| Chiller | Regulates the temperature of the laser and substrate to ensure optimal cladding. |

| Control System | Coordinates the movement of the laser and powder feeder for precision and efficiency. |

Fiber laser cladding provides distinct advantages over traditional methods like arc welding and thermal spraying:

Precision: Fiber laser cladding offers exceptional control over the deposition process, which is difficult to achieve with traditional cladding techniques. This results in smoother, more uniform coatings.

Minimal Distortion: Traditional cladding methods, such as arc welding, involve high heat input, which can distort the substrate material. Fiber laser cladding minimizes heat impact, reducing the risk of thermal distortion and ensuring the integrity of the material.

Material Flexibility: Fiber laser cladding is compatible with a wide range of materials, including metals, alloys, ceramics, and composites. This versatility allows it to be applied in many different industries, from aerospace to medical device manufacturing.

In conclusion, fiber laser cladding is a more efficient and precise method of surface enhancement and repair compared to traditional techniques. Its ability to provide high-quality coatings with minimal distortion and material waste offers significant advantages in terms of performance and cost savings.

| Feature | Fiber Laser Cladding | Traditional Cladding Methods |

|---|---|---|

| Precision | Extremely precise, with minimal distortion | Lower precision, higher distortion |

| Heat Input | Low heat input, minimal substrate distortion | High heat input, risk of warping |

| Material Flexibility | Compatible with various materials (metals, alloys, ceramics) | Limited material compatibility |

| Application Complexity | Can be used on complex geometries and hard-to-reach areas | Difficult for complex shapes or small parts |

The aerospace industry relies heavily on components such as turbine blades, nozzles, and engine parts, which are exposed to extreme stress and harsh operating conditions. These parts experience wear and corrosion over time, requiring effective repair and surface enhancement solutions. Fiber laser cladding has become an essential technology in the aerospace sector, particularly for repairing and enhancing high-performance components.

For example, turbine blades subjected to high temperatures and mechanical stresses can be repaired using fiber laser cladding. This process restores the blades' original dimensions, improves their resistance to further wear, and extends their service life. By applying fiber laser cladding, the surface properties of aerospace components are enhanced, contributing to their overall performance and efficiency.

In the automotive industry, components like camshafts, connecting rods, and brake discs are exposed to significant wear and tear due to constant mechanical stress. Fiber laser cladding helps improve the wear resistance, fatigue strength, and corrosion resistance of these essential automotive parts, ultimately enhancing their performance and longevity.

By using fiber laser cladding, manufacturers can increase the lifespan of automotive components and reduce maintenance costs. The process is particularly valuable for restoring worn-out engine components, offering a cost-effective alternative to part replacement. Precision in material deposition ensures that only the necessary areas are treated, reducing material waste and cost.

Chemical processing equipment, including valves, pipes, and pump casings, is often exposed to harsh chemicals and corrosive environments. This makes it susceptible to corrosion, erosion, and wear, leading to frequent repairs or replacements. Fiber laser cladding provides an effective solution by enhancing the surface properties of these critical components, improving their durability and resistance to harsh conditions.

The cladding process creates a protective layer that significantly improves the equipment's resistance to corrosion and wear, extending its operational life. This technology is particularly valuable in industries like petrochemicals, where equipment is costly and must function under extreme conditions for long periods.

Mining and construction machinery, such as drill bits, gears, and heavy-duty shovels, operate in abrasive environments, making them prone to wear and tear. Fiber laser cladding enhances the surface properties of these components, offering better abrasion resistance and improving their resistance to impact and mechanical stress.

The ability to apply fiber laser cladding to these machinery components reduces the frequency of maintenance or replacement, helping businesses in mining and construction maintain their equipment for longer. This, in turn, reduces downtime and boosts operational efficiency.

| Industry | Applications |

|---|---|

| Aerospace | Repair and surface enhancement of turbine blades, nozzles, and engine parts. |

| Automotive | Strengthening of camshafts, connecting rods, and brake discs. |

| Chemical Processing | Protection of valves, pipes, and pump casings from corrosion and wear. |

| Mining & Construction | Surface enhancement of drill bits, gears, and heavy-duty machinery. |

One of the most significant advantages of fiber laser cladding is the unparalleled precision it offers. The laser beam's intensity, scanning speed, and powder flow rate can be finely controlled, allowing manufacturers to deposit material with exceptional accuracy. This control ensures that the cladding layer is applied with minimal distortion, achieving a uniform surface even on complex geometries. In industries where the quality of components is critical—such as aerospace and automotive manufacturing—this precision is invaluable. For example, in aerospace, turbine blades subjected to extreme temperatures and mechanical stress require precise repairs to restore their integrity without compromising their performance. The ability to control every aspect of the cladding process ensures that these parts meet the highest standards for safety and reliability.

Fiber laser cladding not only improves performance but also offers a cost-effective solution for repairing worn-out or damaged components. Unlike traditional methods that may require full part replacement, fiber laser cladding restores the original specifications of components, extending their service life and improving their functionality. For example, in the oil and gas industry, expensive machinery such as pumps and valves can experience wear due to the harsh operational environments. Rather than replacing these costly parts, fiber laser cladding can restore their surfaces to optimal conditions, saving money on new components and reducing downtime. The ability to repair rather than replace allows companies to cut costs significantly, improving overall profitability while maintaining operational efficiency. In some cases, cladding can even be used to enhance the performance of components beyond their original specifications, providing additional value.

Fiber laser cladding is incredibly versatile, making it suitable for a broad range of materials and applications. It can be used to treat metals, alloys, ceramics, and even composite materials, making it an attractive option for industries with diverse needs. For example, in the medical device manufacturing sector, components that need to be both biocompatible and durable, such as surgical instruments and implants, can benefit from fiber laser cladding. This flexibility is not limited to material compatibility—it also extends to complex geometries. Traditional cladding methods often struggle with intricate shapes or small, hard-to-reach areas. Fiber laser cladding, however, can be precisely controlled to apply coatings on components with intricate designs, ensuring a consistent and effective enhancement of the surface properties. This makes fiber laser cladding ideal for industries such as aerospace, where parts with complex shapes, like turbine blades and engine components, require precise surface enhancement to ensure longevity and performance.

In addition to its technical advantages, fiber laser cladding is also an environmentally friendly process. Unlike traditional methods, such as arc welding and thermal spraying, which can generate significant waste and emissions, fiber laser cladding produces minimal material waste. The laser’s focused energy allows for precise material deposition, reducing the amount of cladding material required and minimizing excess that would otherwise go to waste. Furthermore, the low heat input of the process reduces the need for post-treatment processes, such as grinding or polishing, which can generate additional environmental impact.

The automated nature of fiber laser cladding also improves worker safety. In traditional cladding methods, operators are often exposed to hazardous fumes, intense heat, and physical risks due to manual handling. Fiber laser cladding, however, can be fully automated, with minimal direct human involvement in the high-risk areas of the process. This not only reduces exposure to potentially dangerous substances but also enhances the overall safety of the manufacturing environment. These combined environmental and safety benefits contribute to a cleaner, more sustainable, and safer manufacturing process, aligning with global efforts to improve industrial sustainability and reduce the environmental impact of production activities.

To achieve optimal results with fiber laser cladding, several key parameters must be carefully controlled:

Laser Power: The laser power influences the depth and quality of the cladding layer. Higher power levels result in deeper penetration and more robust coatings.

Scanning Speed: The scanning speed impacts the smoothness and uniformity of the coating. Faster scanning speeds can result in thinner layers, while slower speeds create thicker layers.

Powder Flow Rate: Ensuring a consistent flow of material is essential for achieving uniform deposition and high-quality bonding between the cladding and the substrate.

Carefully optimizing these parameters is crucial for ensuring that the final coating meets the desired specifications without defects.

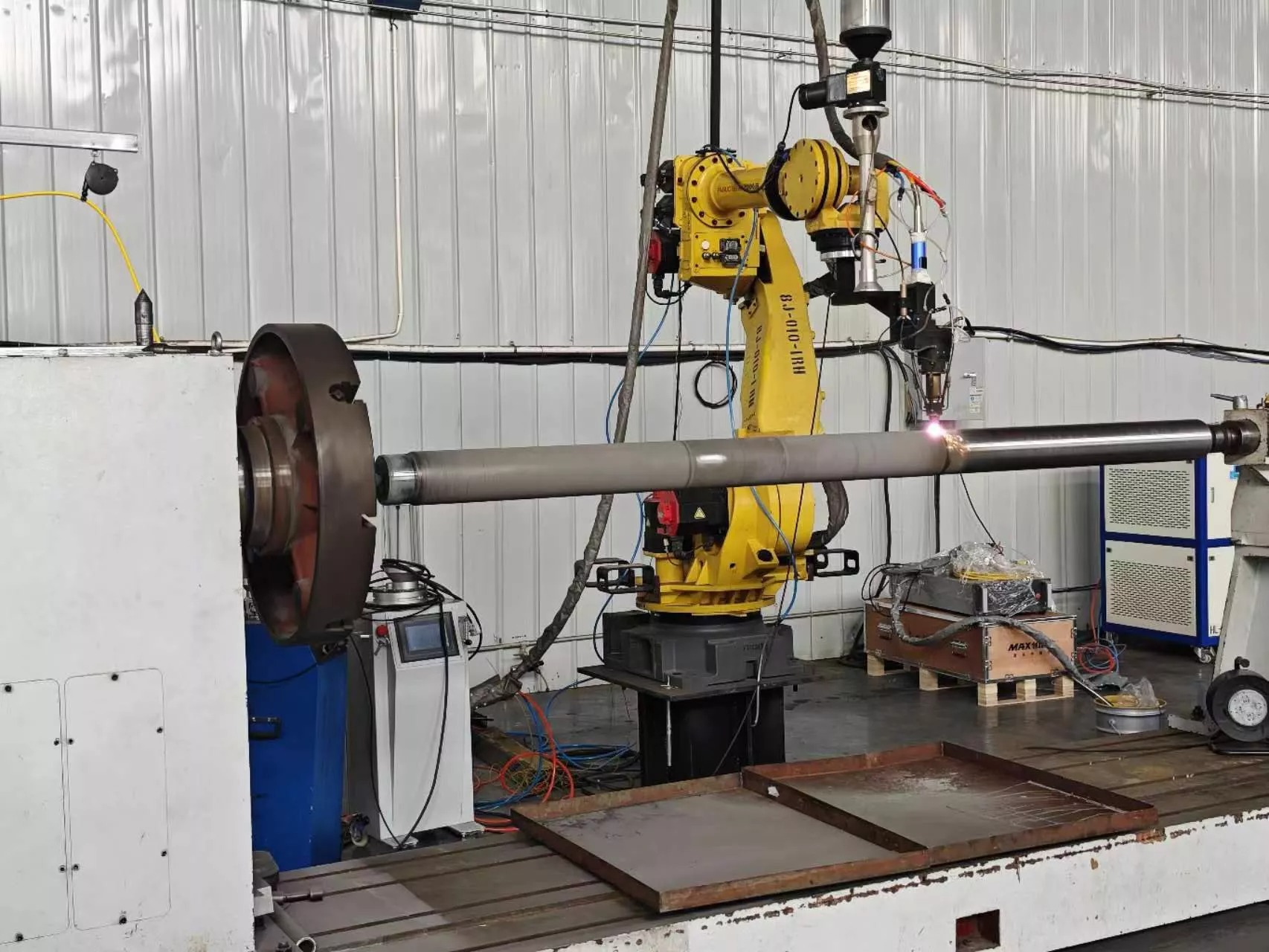

Automation plays a crucial role in improving the efficiency and consistency of fiber laser cladding. Modern machines are equipped with advanced control systems and robotic arms, reducing the need for manual labor and ensuring that each component is processed at optimal levels. Automation also helps streamline the production process, reducing production time and increasing throughput.

Despite its many advantages, fiber laser cladding does come with some challenges, such as heat distortion or uneven powder deposition. However, advancements in laser technology, such as precision beam focusing and improved powder feeders, have minimized these issues significantly. Continuous monitoring during the process further ensures that the quality of the final cladding remains high, meeting the required specifications.

Fiber laser cladding machines are transforming industries by enhancing surface properties with high precision, cost efficiency, and minimal environmental impact. These machines not only improve the durability and performance of components but also reduce operational costs and waste. As the technology evolves, fiber laser cladding will continue to play a critical role in shaping the future of industrial manufacturing.

Fiber laser cladding offers significant advantages in precision and performance. Jinan Pioneer CNC Technology Co., Ltd. provides advanced fiber laser cladding machines that ensure efficiency, reliability, and cost savings across various sectors. Their products enhance component life while offering valuable, sustainable manufacturing solutions.

A: A Fiber Laser Cladding Machine uses a high-powered laser beam to melt metal powder or wire, bonding it to a substrate to enhance surface properties like wear and corrosion resistance.

A: Fiber laser cladding restores and strengthens critical aerospace components, such as turbine blades, by creating durable, wear-resistant coatings that extend their operational life.

A: Fiber laser cladding offers higher precision, reduced heat input, and minimal material waste compared to traditional methods like arc welding or thermal spraying, making it more efficient and cost-effective.

A: Industries such as aerospace, automotive, chemical processing, and mining can greatly benefit from fiber laser cladding for enhancing component durability and reducing maintenance costs.

A: Fiber laser cladding is versatile, capable of cladding materials like metals, alloys, ceramics, and composites, making it suitable for various industrial applications.

A: Fiber laser cladding produces minimal waste and uses less material, contributing to a cleaner, more sustainable manufacturing process compared to traditional cladding methods.