Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

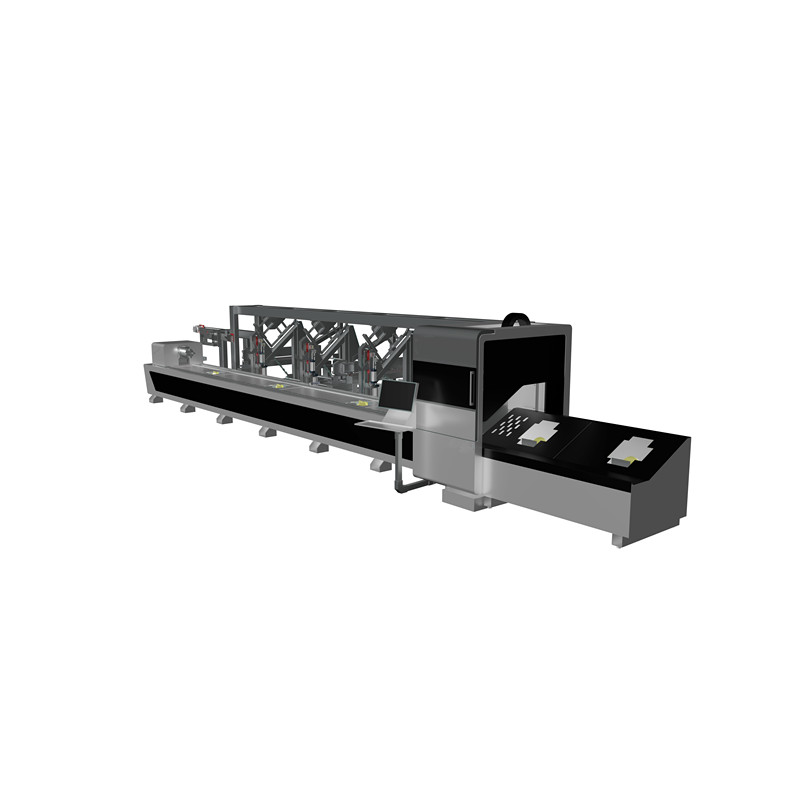

Fiber laser cutting machines are revolutionizing industries by offering unmatched precision and speed. These machines are now essential in modern manufacturing, especially for cutting metals like stainless steel and aluminum. In this guide, we will explore the basics of fiber laser cutting, how it works, and key tips for beginners. You will gain insights into choosing the right machine, setting it up, and ensuring optimal performance for your projects.

A fiber laser cutting machine uses a high-powered laser beam to cut materials with incredible precision. It operates by focusing the laser beam on the material's surface, where intense heat melts or vaporizes the material, and assist gases are used to remove the molten metal.

Key components of a fiber laser cutting machine include:

Laser Source: Generates the laser beam.

Optics: Direct the beam toward the material with precision.

Cooling System: Maintains an optimal temperature to prevent damage.

CNC System: Controls the movement of the laser head and machine axes for accurate cuts.

The cutting process begins when the fiber laser generates a concentrated beam of light. This beam is focused on the material, where the heat causes the material to melt or vaporize. The assist gases, such as oxygen or nitrogen, blow away the molten material, leaving a clean cut.

Assist gases play a crucial role in the cutting process. Oxygen is often used for cutting carbon steel, while nitrogen is preferred for materials like stainless steel and aluminum to ensure clean, oxide-free edges.

Fiber lasers have significant advantages over other cutting methods:

CO2 Lasers: While CO2 lasers are suitable for non-metals, fiber lasers outperform them in metal cutting due to their shorter wavelength.

Plasma Cutting: Plasma cutters are slower and less accurate than fiber lasers, making them less suitable for intricate cuts.

Mechanical Cutting: Unlike traditional methods, fiber lasers don't contact the material, reducing wear and tear on the machine and ensuring cleaner cuts.

Advantages of Fiber Laser Cutting:

Faster cutting speeds

Higher precision

Cost-effective for long-term use due to lower maintenance needs

Choosing the right fiber laser cutting machine depends on your specific production needs. Consider the types of materials you frequently cut (e.g., carbon steel, stainless steel, aluminum) and their thickness. Also, assess whether your production volume is high (requiring faster cutting speeds) or low (where precision is more important).

Laser Power: The power rating of the laser will determine the maximum thickness and speed for cutting. For example, a 1 kW machine is ideal for thinner materials, while a 6 kW machine can handle thicker metals.

Focal Length: This determines the focus of the laser beam. Shorter focal lengths are ideal for cutting finer details, while longer focal lengths are suitable for thicker materials.

Cutting Speed: Faster cutting speeds increase efficiency but can reduce precision. Select a machine with adjustable speed settings for optimal performance.

For beginners, simplicity is key. Look for CNC systems with easy-to-understand interfaces that support various file formats like G-code and DXF. Some machines offer automation features such as auto-focus and automatic loading/unloading, which can greatly improve cutting efficiency and reduce the need for manual intervention.

Tip: When purchasing a fiber laser cutter, ensure it comes with a comprehensive user manual and that the vendor offers after-sales support.

Before you start cutting, it’s essential to properly set up the fiber laser cutting machine:

Power On: Ensure the laser source and cooling system are operational.

Material Preparation: Clean and secure the material on the cutting bed. For best results, make sure the material is flat and free from contaminants.

Inspect Components: Check the lens, mirrors, and nozzles for any dirt or damage that could affect the cutting quality.

Design files need to be in a vector format such as G-code, DXF, or DWG. The design software you use (e.g., Adobe Illustrator, CorelDRAW) should be able to export files in a format that your fiber laser cutting machine can read. Once the file is prepared, it is transferred to the machine via USB, Ethernet, or network connection.

To achieve high-quality cuts, it's crucial to adjust the laser settings based on the material being cut:

| Power | Higher power is needed for thicker materials but can cause burns on thinner materials. |

| Speed | Faster speeds improve efficiency but can reduce the precision of the cut. |

| Focus | Adjusting the focus is critical for achieving clean cuts. Ensure the laser is focused on the material’s surface or slightly above, depending on the thickness. |

Once you begin the cutting process, it’s essential to monitor the machine to ensure everything is running smoothly. Check for issues like misalignment, uneven cutting, or excess heat. Always follow safety protocols and keep an eye on the material as it’s being cut.

To keep your fiber laser cutting machine running efficiently, it’s essential to perform regular maintenance:

Clean Lenses and Mirrors: Dust and debris can affect the laser's precision. Clean lenses regularly using appropriate cleaning materials.

Check the Cooling System: Ensure that the cooling system is functioning properly and that the water temperature remains within the optimal range.

Over time, components like lenses, nozzles, and assist gas supplies will need to be replaced. Regularly check for wear and tear and replace consumables as needed to maintain cutting quality.

Some common issues include uneven cutting, burned edges, and misalignment. These problems are often due to incorrect laser settings, dirty lenses, or improperly secured materials. Troubleshoot by adjusting parameters and ensuring the machine is clean and calibrated.

Operator safety is paramount when using fiber laser cutting machines. Always wear appropriate PPE, including protective eyewear to shield your eyes from the laser. Ensure that your work area is well-ventilated and free of flammable materials.

To prevent accidents, ensure that the cutting area is enclosed to minimize exposure to the laser beam. Always follow fire safety protocols and keep a fire extinguisher nearby in case of emergencies.

Proper training is essential for anyone operating a fiber laser cutting machine. Ensure operators are familiar with machine settings, safety procedures, and maintenance practices. Consider investing in certification programs to ensure your team is well-prepared.

Fiber laser cutting is widely used across industries like automotive, aerospace, and construction for creating high-precision parts. These machines excel at cutting thick metals quickly and accurately, making them ideal for high-demand production environments.

Fiber laser cutters aren’t just for industrial applications—they’re also great for small businesses and custom products. Whether it’s creating custom signage, engraving jewelry, or cutting detailed artwork, a fiber laser cutter can open up new creative possibilities.

As technology evolves, fiber laser cutting machines continue to improve. Advancements include higher-powered lasers, faster cutting speeds, and more automated systems. The future will see fiber lasers playing an even bigger role in industries like green energy and medical devices, where precision and efficiency are paramount.

Fiber laser cutting machines offer unmatched speed, precision, and versatility across various applications. By understanding the technology and selecting the right machine, beginners can fully maximize their potential. Pioneer CNC provides advanced products that help meet the demands of both manufacturing and creative production. Their machines, known for their efficiency and durability, offer great value to users seeking high-performance laser cutting solutions.

A: A fiber laser cutting machine uses a concentrated laser beam to cut materials like metals with high precision. It works by focusing the laser onto the material’s surface, where intense heat melts or vaporizes it.

A: The machine directs a laser beam onto the material, where the heat causes the material to melt or vaporize. Assist gases, like oxygen or nitrogen, blow away the molten material, ensuring a clean cut.

A: Fiber laser cutting machines offer unmatched precision, speed, and efficiency, making them ideal for industries requiring high-quality cuts, like automotive and aerospace.

A: Compared to traditional cutting methods, fiber lasers provide faster cutting speeds, reduced material waste, and higher accuracy, making them more cost-effective and efficient in the long run.

A: The cost of a fiber laser cutting machine varies based on its power, size, and features. Generally, entry-level machines may cost around $20,000, while more advanced models can exceed $100,000.

A: Regular maintenance involves cleaning lenses and mirrors, checking the cooling system, and replacing consumables like nozzles and assist gases to ensure optimal performance.

A: Fiber laser cutting machines can cut a variety of metals, including stainless steel, aluminum, copper, and brass. They are highly effective for cutting thin to medium-thick materials.