Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

Fiber laser cutting machines are transforming industries with their precision and speed. From aerospace to automotive, these machines are revolutionizing material processing.

In this guide, we'll explore the essentials of fiber laser cutting machines, including key components, power selection, and cutting speed. You'll learn how to maximize efficiency and choose the right machine for your needs.

Fiber laser cutting machines utilize a high-intensity laser beam generated by fiber optic technology to cut through materials with exceptional precision. Unlike traditional CO2 lasers that use gas to amplify the laser, fiber lasers use an optical fiber to produce the laser beam. This results in a more efficient and reliable process, with higher beam quality and greater energy efficiency.

The fiber laser beam is transmitted through a flexible fiber-optic cable to the cutting head, where it’s focused onto the material. The intense heat from the laser melts or vaporizes the material, and an assist gas helps blow away the molten material, leaving a clean and precise cut.

The fiber laser cutting process follows several steps:

| Laser Generation | The laser beam is produced by the fiber laser source. |

| Beam Delivery | The beam is transmitted through fiber optics to the cutting head. |

| Focus and Cut | The cutting head focuses the beam to a fine point, which melts or vaporizes the material at the desired cutting path. |

| Assist Gas | Gases like oxygen or nitrogen are used to blow away molten material, ensuring clean cuts. |

Tip: To get optimal results from your fiber laser cutter, always ensure the assist gas is suited to the material you're cutting. Nitrogen works best for aluminum, while oxygen is more efficient for carbon steel.

One of the first considerations when selecting a fiber laser cutting machine is power. The laser power determines how thick a material you can cut, as well as how quickly it can be cut. Here's a general guideline for selecting the right power based on material thickness:

Steel up to 1/4 inch: 1.5 kW

Steel up to 3/8 inch: 2 kW

Steel up to 1/2 inch: 3 kW

Steel up to 1 inch: 6 kW

There are various types of fiber laser cutters, ranging from lower-powered machines designed for light-duty use to high-powered industrial machines suited for large-scale production. Machines typically range from 1.5 kW to 6 kW in power capacity. For small businesses or personal use, a 1.5 kW to 2 kW machine may be sufficient. For large-scale industrial applications, machines with 6 kW or more may be necessary.

Laser power impacts the cutting speed, material thickness capacity, and quality. Higher laser power allows for faster cutting and the ability to handle thicker materials. However, it also requires more energy and can affect the cutting edge quality. The key is finding a balance that matches your material and performance requirements.

Cutting speed and quality are closely related. Faster cutting speeds can reduce production time, but they may come at the cost of edge quality. It’s essential to find the right speed for your application. Slower speeds often result in cleaner cuts, while faster speeds might require a compromise in edge smoothness.

The focal length of a fiber laser cutter plays a significant role in the precision of the cut. Shorter focal lengths, such as 1.5 inches, are ideal for detailed and intricate cuts on thin materials. Longer focal lengths, such as 5 inches, are better for cutting thicker materials but may sacrifice some detail.

Oxygen: Best for cutting thick carbon steel, providing a faster cutting speed.

Nitrogen: Ideal for stainless steel and aluminum, offering high-quality cuts with minimal oxidation.

Air: Used for thinner materials and non-ferrous metals.

The choice of assist gas depends on the material being cut and the desired result. Oxygen can be used for faster cutting of carbon steel but may not work well with non-ferrous metals. Nitrogen, though more expensive, delivers high-quality cuts with minimal oxidation, making it the preferred choice for stainless steel and aluminum.

The type of gas used can significantly affect cutting speed and edge quality. Oxygen accelerates the cutting process but can leave a rougher edge, while nitrogen produces a smoother cut but at a slower speed.

Fiber laser cutters are widely used in the manufacturing and metalworking industries, including applications in aerospace, automotive, and heavy machinery. The ability to cut various metals like steel, aluminum, and titanium with precision makes them invaluable for producing high-quality components and parts.

Case Study: In aerospace manufacturing, fiber laser cutting machines have reduced the time required to cut titanium sheets, improving productivity and reducing costs.

Fiber laser cutting machines are not limited to industrial applications. In fact, they’re making waves in creative industries like jewelry making, art, and textiles. Fiber lasers can cut intricate designs in metals and fabrics, providing an efficient solution for highly detailed products.

Before beginning a project, ensure that your fiber laser cutting machine is properly set up. Start by verifying that the cooling system is functioning and that all components are clean. Inspect the alignment and ensure that lenses and nozzles are properly in place.

Preparing design files for fiber laser cutting requires the use of specific formats like DXF, DWG, or G-code. Ensure that the design is in the correct scale and format to avoid errors during the cutting process.

Once everything is set, power on the machine and load the material. Make sure to follow all safety protocols, such as wearing protective gear and ensuring the work area is clear of hazards. Regularly monitor the cutting process to ensure everything runs smoothly.

Regular maintenance is critical to ensuring the long lifespan of your fiber laser cutting machine. Clean the lenses and inspect critical components like the cutting head and nozzles. Check the cooling system and verify that the assist gas is in good supply.

Some common issues you may encounter include uneven cuts, power inconsistencies, or misalignment. These problems can often be traced to the machine's settings, gas pressure, or alignment. Perform a diagnostic check and make adjustments as necessary.

The future of fiber laser cutting is marked by advancements in automation, multi-material processing, and integration with AI systems. These innovations will increase the precision, speed, and adaptability of machines, allowing for even more complex and diverse applications.

As industries move towards sustainable production, fiber laser cutting machines are becoming more energy-efficient. Expect future models to feature energy recovery systems and eco-friendly exhaust systems to minimize environmental impact.

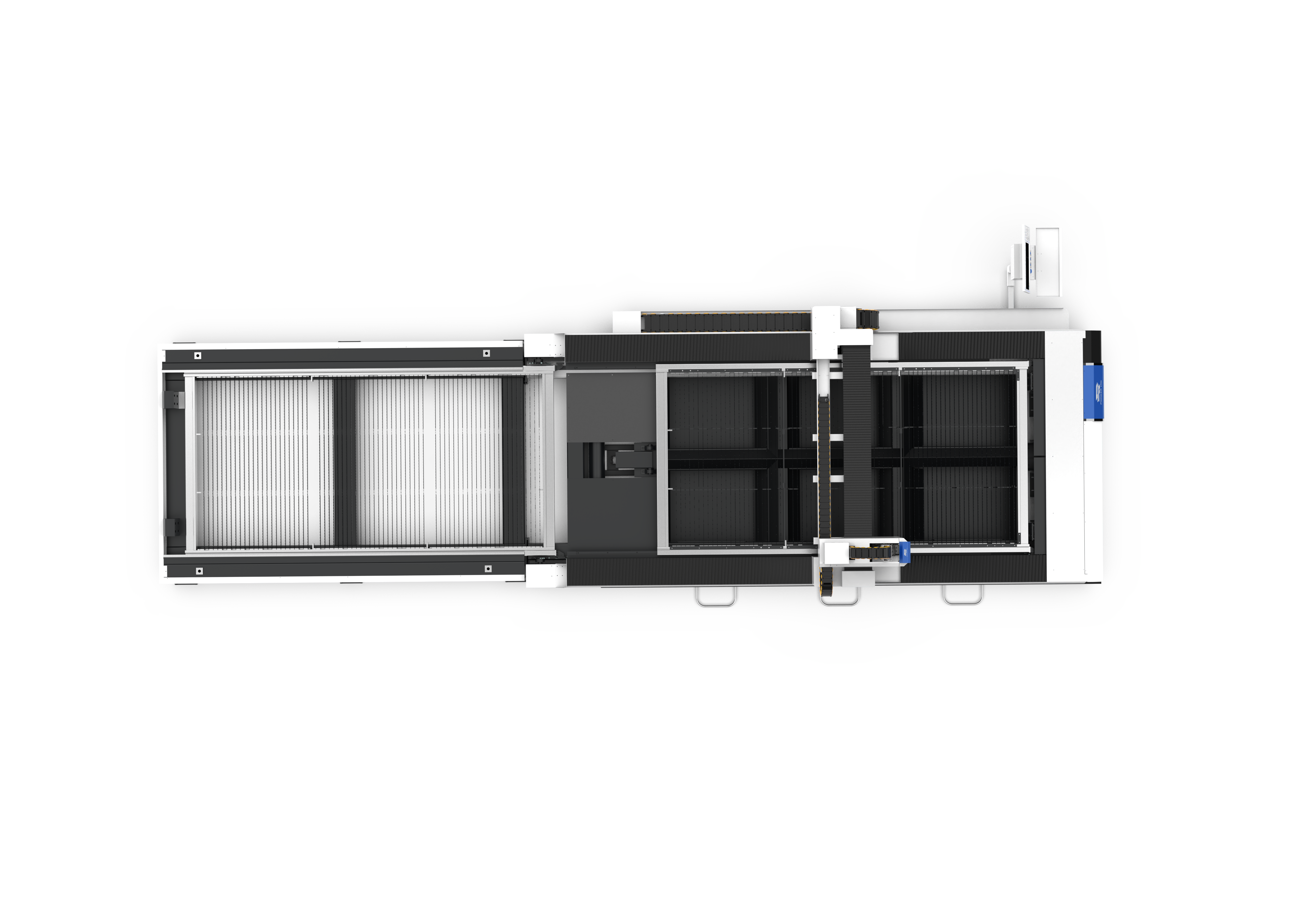

Fiber laser cutting machines are revolutionizing industries with speed, precision, and versatility. Whether for manufacturing or creative sectors, understanding how to select, operate, and maintain these machines is key to success. By focusing on laser power, speed, and assist gas, businesses can improve efficiency and reduce costs. Pioneer CNC offers high-quality fiber laser cutting machines that deliver exceptional performance, ensuring businesses can meet their production needs while maintaining high standards.

A: A Fiber Laser Cutting Machine uses a high-intensity laser beam generated by fiber optics to cut through materials like metals with precision. It’s more efficient than traditional CO2 lasers and is widely used in industries for faster and cleaner cuts.

A: The machine generates a laser beam that is focused on the material's surface. The intense heat melts or vaporizes the material, and assist gas blows away the molten material, ensuring a precise cut.

A: Fiber lasers offer faster cutting speeds, better precision, and higher energy efficiency compared to traditional methods. They also require less maintenance and have lower operating costs.

A: Consider factors like material thickness, laser power, and cutting speed. For thicker materials, opt for a higher-powered machine. For faster production, focus on speed and cutting quality.

A: The cost of a Fiber Laser Cutting Machine varies based on power capacity and size. Prices typically range from a few thousand to tens of thousands of dollars, depending on the features and intended application.

A: Fiber laser machines can cut a variety of materials, including metals like stainless steel, aluminum, carbon steel, and titanium. They are ideal for both thin and thick materials.

A: Regular maintenance includes cleaning lenses, checking nozzles, and inspecting the cooling system. It’s also important to monitor the assist gas levels and ensure the machine is properly aligned.

A: Fiber laser cutting machines provide greater accuracy, faster cutting speeds, and better overall efficiency compared to other machines, especially for metal cutting. They are also more energy-efficient and require less maintenance.