Views: 0 Author: Site Editor Publish Time: 2025-10-19 Origin: Site

Laser cutting technology has transformed industries like aerospace and automotive, offering speed and precision. CO2 lasers and Fiber Laser Cutting Machines are two popular options, each with distinct advantages.

In this article, we will explore the differences between these two technologies. You’ll learn how to choose the right laser for your material, application, and production goals.

Laser cutting technology plays an integral role in industries that require high precision, such as electronics, automotive, and manufacturing. The two most common types of lasers are CO2 lasers and Fiber Laser Cutting Machines. While both are designed to cut materials efficiently, they each offer different advantages depending on the material and the specific requirements of the job.

Understanding the fundamental differences between these technologies can help you decide which one best suits your business, whether you’re cutting thin metals, thick plastics, or intricate components.

A CO2 laser cutter utilizes a gas-filled tube to produce a laser beam by stimulating carbon dioxide molecules. The generated infrared light is directed through a series of mirrors and focused to cut various materials.

Versatility: CO2 lasers are highly effective for cutting non-metal materials like wood, acrylic, plastic, and textiles.

Ideal for Thicker Materials: CO2 lasers perform well when cutting thicker materials, making them the go-to option for industries dealing with metals over 5 mm thick.

Proven Technology: As a long-established technology, CO2 lasers have a reliable track record across many industries, from medical to food production.

High Energy Consumption: CO2 lasers are less energy-efficient, converting only about 10-15% of their energy into usable laser output, leading to higher operational costs.

Maintenance Demands: Regular maintenance, including cleaning and replacing mirrors, is essential to ensure the lasers continue to perform at their best.

Limited Efficiency with Reflective Materials: CO2 lasers struggle with highly reflective materials like aluminum, which can cause damage to the machine’s components.

Fiber lasers use solid-state technology, where a laser diode is pumped through a fiber optic cable, which amplifies the laser energy. The laser beam is then directed through the fiber optic system to the cutting head.

Superior Precision: Fiber Laser Cutting Machines excel at cutting thin materials with high precision, producing smoother, finer cuts.

Energy Efficiency: Fiber lasers are highly efficient, typically converting up to 90% of energy into usable output, which significantly reduces energy consumption and operating costs.

Minimal Maintenance: Fiber lasers have fewer parts, reducing the need for maintenance. The beam is delivered through fiber optics, eliminating the need for frequent cleaning of mirrors.

Thicker Materials: Fiber lasers are not as effective for cutting thick metals (over 15 mm), especially without additional assistance like oxygen or nitrogen.

Challenges with Non-Metal Materials: Fiber lasers face difficulty cutting non-metals like wood, plastics, and rubber, which CO2 lasers handle better.

CO2 Lasers: Best for cutting non-metallic materials such as wood, acrylic, plastics, and textiles. CO2 lasers also work well with metals but struggle with highly reflective ones.

Fiber Lasers: More effective for cutting metals, particularly highly reflective ones like stainless steel, brass, and aluminum.

Fiber Laser Cutting Machine: Fiber lasers are faster, especially when cutting thin metals (less than 8 mm). Their higher precision and cutting speed make them ideal for high-speed production lines.

CO2 Lasers: While CO2 lasers are slower for thinner materials, they excel in cutting thicker materials efficiently.

Fiber Lasers: Provide higher precision and cleaner edges on thinner materials, resulting in minimal dross and finer cuts.

CO2 Lasers: Generally, CO2 lasers offer smoother edges on thicker materials but may leave some roughness when cutting thin materials.

Fiber Laser Cutting Machine: With energy efficiency upwards of 90%, fiber lasers significantly reduce power consumption compared to CO2 lasers.

CO2 Lasers: These are less efficient, consuming much more power (around 10%) to achieve the same cutting results, leading to higher operational costs over time.

For Thin Metal Sheets: Fiber Laser Cutting Machines are more efficient and faster, making them a better choice for applications involving thin metal sheets.

For Thicker Materials: CO2 lasers may be a better option, especially for materials above 5 mm. They can handle thicker materials more effectively, often with the help of additional gases like oxygen.

Upfront Costs: CO2 lasers tend to have a lower initial cost, making them more accessible for businesses on a budget.

Long-Term Costs: Fiber lasers offer lower long-term operational costs due to their higher energy efficiency and lower maintenance needs.

Fiber Lasers: Best for high-precision, high-speed applications, particularly in industries such as automotive, aerospace, and electronics.

CO2 Lasers: Better for slower, high-quality cuts on thicker materials, particularly where fine details are not as critical.

Low Maintenance: Fiber lasers have minimal moving parts, which means less time and money spent on repairs and maintenance.

Cost Savings: Due to their high energy efficiency and low maintenance demands, fiber lasers offer significant cost savings over their operational lifespan.

Frequent Maintenance: CO2 lasers require more frequent maintenance, such as mirror cleaning and part replacements.

Higher Operational Costs: With lower energy efficiency, CO2 lasers result in higher electricity and gas consumption, raising overall costs.

Industries: Medical, food production, textiles, and manufacturing industries benefit from CO2 lasers’ ability to cut non-metallic materials.

Non-Metal Cutting: CO2 lasers are more suitable for industries where plastics, wood, and textiles need to be cut with high precision.

Industries: Automotive, aerospace, electronics, and telecommunications industries benefit from fiber lasers’ ability to cut metals like stainless steel, brass, and aluminum.

Metal Cutting: Fiber lasers are better suited for applications where precision and speed are essential in metal cutting.

| Feature | CO2 Laser Cutters | Fiber Laser Cutting Machines |

|---|---|---|

| Best For | Non-metals, thicker materials (wood, plastics, textiles) | Thin metals, high precision cutting |

| Material Compatibility | Works well with wood, acrylic, rubber, plastics, and metals | Best for metals, including reflective ones like stainless steel, brass |

| Cutting Speed | Slower for thin materials, faster for thicker metals | Faster for thin materials (<8mm) |

| Energy Efficiency | Low efficiency (~10%) | High efficiency (up to 90%) |

| Precision | Smooth edges on thicker materials, lower precision on thin materials | Higher precision, cleaner cuts on thin metals |

| Maintenance | Frequent maintenance (mirror cleaning, part replacement) | Low maintenance, fewer parts to maintain |

| Operational Costs | Higher due to low energy efficiency | Lower due to better energy conversion |

| Ideal Industries | Textiles, food production, medical | Automotive, aerospace, electronics |

| Initial Cost | Generally lower initial cost | Higher initial cost but lower long-term costs |

| Lifespan | Shorter lifespan, higher wear and tear | Longer lifespan, less wear and tear |

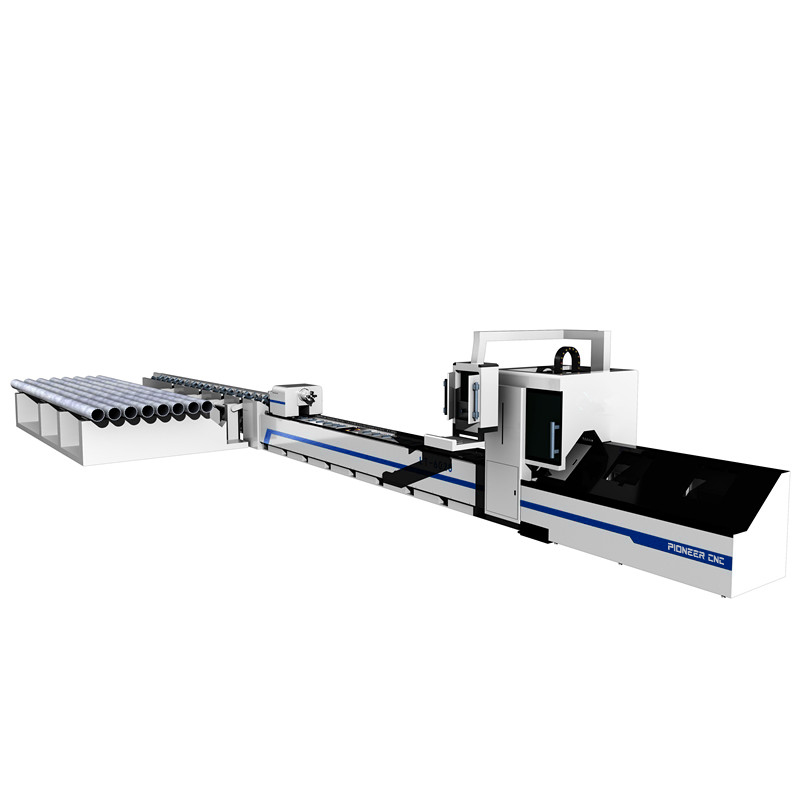

When choosing between CO2 lasers and Fiber Laser Cutting Machines, key factors like material type, thickness, precision, energy efficiency, and operating costs must be considered.For businesses focusing on thin metals and requiring high precision, fiber lasers offer faster speeds, lower costs, and longer lifespans. For thicker materials or non-metals, CO2 lasers may be more cost-effective. Pioneer CNC provides high-quality laser cutting solutions, offering machines that ensure high precision and cost-efficiency.

A: CO2 lasers are ideal for non-metals and thicker materials, while Fiber Laser Cutting Machines are more efficient for cutting thin metals with high precision.

A: Fiber Laser Cutting Machines generally have lower long-term operational costs due to better energy efficiency, though CO2 lasers may have lower initial costs.

A: Fiber Laser Cutting Machines are less effective at cutting thicker materials compared to CO2 lasers but can still handle materials up to 20mm with adjustments.

A: If precision, speed, and cutting thin metals are your priorities, Fiber Laser Cutting Machines offer faster speeds, lower operational costs, and longer lifespans.

A: Fiber Laser Cutting Machines are ideal for high-precision industries like automotive and aerospace, while CO2 lasers are better suited for textiles and food production.

A: Fiber Laser Cutting Machines require less maintenance due to fewer moving parts, while CO2 lasers need frequent mirror cleaning and part replacements.